What is the difference between SIL and SIS?

What is the difference between SIL and SIS?

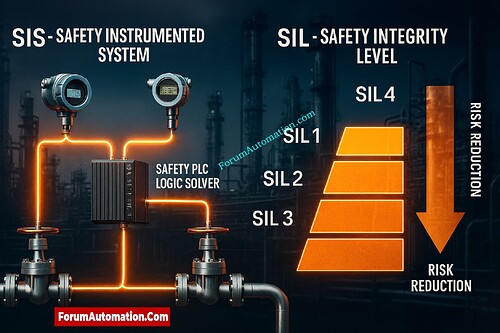

SIL (Safety Integrity Level) and SIS (Safety Instrumented System) are two words that are quite similar in functional safety, but they mean different things when it comes to reducing risk in industrial process facilities.

The Safety Instrumented System (SIS) is the real safety system that is in place at a plant. There are sensors (like pressure, level, or temperature transmitters), a logic solver (a safety PLC or relay system), and final control elements (such shutdown valves, motor trips, and relays). The SIS keeps an eye on dangerous process conditions all the time and automatically takes action to fix them, including turning off equipment or cutting off energy supplies, when safety thresholds that have been set are surpassed. There may be one or more Safety Instrumented

Functions (SIFs) in each SIS. Each SIF is meant to stop or lessen the effects of a certain dangerous event. Standards like IEC 61511 govern the design, use, and upkeep of SIS. But a Safety Integrity Level (SIL) is not a system. It is a number that shows how reliable and well a SIF needs to work within the SIS. SIL tells you how well a safety function must lower risk. There are four levels: SIL 1, SIL 2, SIL 3, and SIL 4. SIL 4 is the level that reduces risk the most. For systems with low demand, SIL is shown as the Probability of Failure on Demand (PFDavg), while for systems with high demand, it is shown as the Probability of Dangerous Failure per Hour (PFH).

SIS is the hardware and logic that carries out safety actions, while SIL is the performance goal that the SIS (or a specific SIF) must reach. An SIS is built and tested to satisfy a specified SIL, which makes sure that the plant’s risk is kept to a safe level.