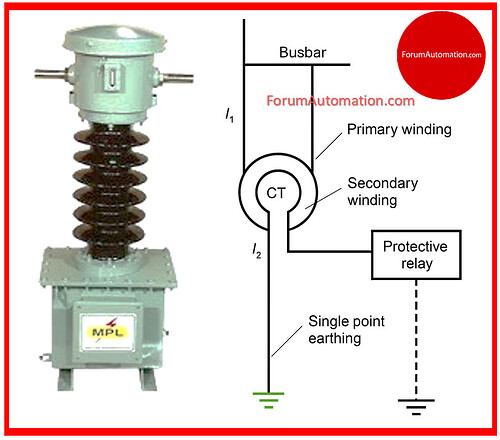

Single-Point Earthing in CTs is essential for the safety, accuracy, and effective operation of the protection and measurement system. It is usually applied to the secondary side, not the primary.

Safety Purpose

CTs have a high primary current and low secondary voltage. However, if the secondary is left open (or) floating (not grounded), significant voltages may occur owing to inductive kickback or insulation failure.

Single-point earthing prevents harmful voltages from entering the secondary circuit, protecting both personnel and equipment.

Avoid Ground Loops

Grounding the CT secondary at various sites causes ground loops, which can cause measurement errors (or) relay malfunction.

As a result, only one earthing point is necessary, which is normally located on the panel side.

Protection System Accuracy

Accurate CT secondary currents are necessary for relays to function properly.

Ground potential differences (or) loop currents can confuse actual current measurements, impairing the performance of differential, overcurrent (or) distance relays.

Primary Side – No Earthing

The primary side of the CT delivers the system current & is already connected to the system ground via the power circuit.

It doesn’t need a separate earthing from the CT.

Ground just one point of the CT secondary circuit, never open (or) ground multiple points. The primary side does not require a separate earthing from the CT.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.