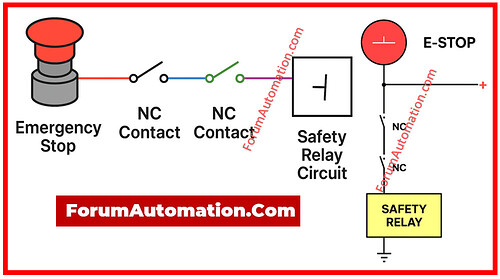

In a safety relay circuit, Emergency Stop (E-Stop) push button utilizes two normally closed (NC) contacts.

Emergency Stop push buttons utilize two NC contacts to enable dual-channel redundancy & fault monitoring, ensuring system safety even if one channel fails.

Redundancy (Dual-Channel Safety)

Emergency stop circuits must be redundant, according to safety regulations (IEC 60204, ISO 13849 and IEC 62061).

Two NC contacts indicate two distinct signal channels to the safety relay.

If one contact fails (for example, welded shut), the other can still break the circuit and stop the machine.

Fault Detection (Cross-Monitoring)

Safety relays constantly check both NC channels.

If one contact opens while the other remains closed (due to a malfunction), the relay recognizes the mismatch.

This prevents a misleading expectation that the machine is protected when one channel fails.

Ensures Fail-Safe Operation

When NC contacts are closed in normal conditions, the circuit is powered.

Pressing the E-Stop button causes both NC contacts to open, resulting in power loss.

Even just one contact sticks (or) breaks, the system will detect a dangerous condition.

Prevents Bypass (or) Single-Point Failure

With only 1 NC contact, a welded contact (or) wire short might render the E-Stop inoperable.

Dual NC contacts lessen the possibility that a single failure may disable the safety feature.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.