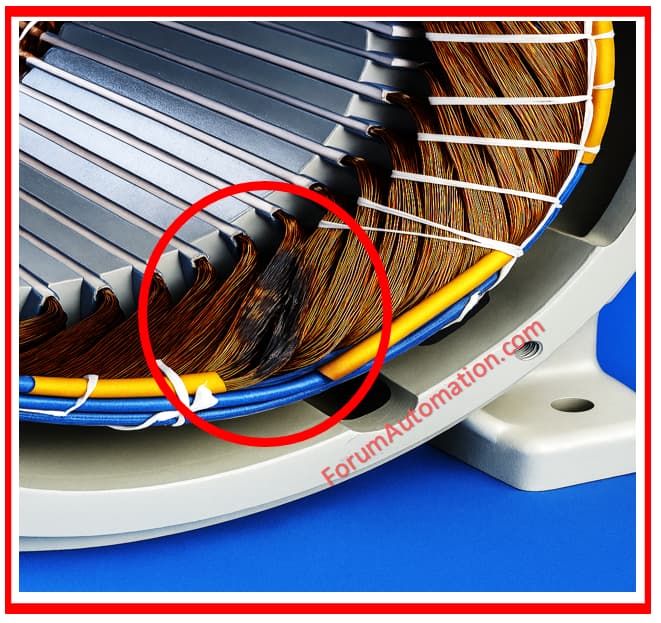

Turn-to-turn winding failure in VFD-fed electric motors happens mostly in the initial few spins of the stator winding, which are directly exposed to the steep voltage waveforms created by Variable Frequency Drives (VFDs).

Unlike sinusoidal supplies, VFDs provide fast-rising PWM (Pulse Width Modulated) voltage pulses with a very high dv/dt (rate of voltage rise).

The first few spins of the motor winding experience the most electrical stress due to uneven voltage distribution resulting in

- Partial discharges,

- Insulation degradation and

- Eventual collapse.

Over time, this stress reduces the insulation between adjacent turns resulting in localized heating and turn-by-turn short circuits.

This is why VFD-fed motors are more prone to early insulation failures in the first few spins of the winding than motors powered by a pure sinusoidal source.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.