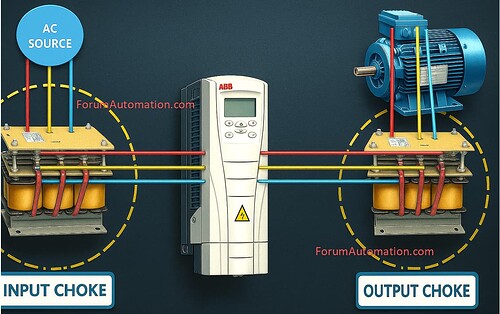

Input and output chokes are essential components of Variable Frequency Drive (VFD) systems, designed to

- Improve performance,

- Improve power quality and

- Protect the connected equipment.

Input Choke

An input choke added on the supply side of the VFD minimizes harmonics created by the drive’s rectifier step.

These harmonics can distort the input current waveform compromising power quality and surrounding equipment.

By increasing the circuit’s impedance the input choke reduces harmonic currents stabilizes the input voltage & improves overall power factor.

It also protects the VFD from the grid disturbances which include voltage spikes (or) transients, assuring smooth and dependable performance.

Output Choke

An output choke installed between the VFD and the motor addresses problems created by the high-frequency switching of the VFD’s PWM output.

These quick switching occurrences generate high dv/dt (rate of voltage change) & voltage spikes that can cause insulation stress and premature motor failure.

The output choke minimizes out voltage spikes, lowers dv/dt stress and reduces electromagnetic interference (EMI).

It also reduces the effects of voltage reflections especially in systems with lengthy cable lengths thereby protecting the motor windings and ensuring reliable current supply.

In simple terms, input chokes optimize the power supply to the VFD whereas output chokes protect the motor and ensure that the entire system runs safely.

Both are essential for increasing system reliability & extending equipment life.