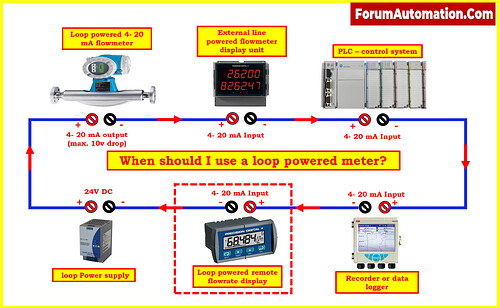

- In the area of industrial instrumentation, a loop-powered meter, also called a 4-20 mA meter, is a common tool for measuring different process parameters.

- A 4-20 mA current loop gives it power and lets it send and receive information.

- Here, we’ll discuss about when and why you should use a loop-powered meter with analog signal loops.

We’ll also talk about its benefits and uses.

Benefits of loop-powered meters:

Simple and Reliable:

- Loop-powered meters are known for being simple and reliable.

- They need less wiring and are less likely to lose their signal over long distances than signs based on voltage.

Intrinsically Safe:

- They are safe to use in dangerous places because the low current levels (4-20 mA) make it less likely that sparks or fires will happen.

Power efficiency:

- Loop-powered meters use very little power, so they can be used with batteries or in places where power isn’t always available.

continuing Monitoring:

- The 4-20 mA signal gives ongoing measurements in real time, so changes in the process can be dealt with right away.

When to Use a Loop-Powered Meter:

Remote Monitoring:

- When the measurement site is located a long way from the control room or central monitoring station, loop-powered meters are the best option.

- They are frequently employed in applications related to water treatment, environmental monitoring, and oil and gas because they can send signals over long distances without suffering considerable signal loss.

Hazardous Areas

- Due to their intrinsic safety, loop-powered meters are recommended in potentially explosive or hazardous environments like chemical factories, refineries, or mining activities.

- Because of the reduced risk of ignition caused by the low current levels, they are a safe option.

Battery-Powered Devices

- Loop-powered meters are a great choice for measuring devices that need to be driven by a battery because they use minimal power.

- This is helpful for things like wireless sensor networks, remote sensor nodes, and portable instruments.

- Reduced Wiring Costs: Loop-powered meters reduce the need for wiring. Installation costs are lower because they only need two wires (plus ground, if needed) to send both power and signals.

- This is different from voltage-based systems, which need separate cables for power and signals.

Analog Signal Transmission

- Loop-powered meters are better for sending analog signals over long distances because they are less likely to have voltage drop or electrical noise.

- This makes them good for measures of temperature, pressure, and level, where keeping the signal’s integrity is very important.

Process Control

- In industrial process control systems, meters that are driven by a loop are often used.

- They give continuous info that can be used to make changes to the process in real time, making sure it runs smoothly and efficiently.

Monitoring the Environment

- Loop-powered meters are useful for tracking things like air quality, water quality, and emissions as part of monitoring the environment.

- Because they are reliable and can send info over long distances, they can be used to check on conditions in remote or hard-to-reach places.

Standardization of Instrumentation

- The 4-20 mA standard is used by many businesses as a common way to discuss instrumentation.

- Using meters that are powered by a loop makes it easy to standardize and add new devices to existing systems.