What role does the IIoT play in present-day PLC applications?

The Role of IIoT in Modern PLC Applications

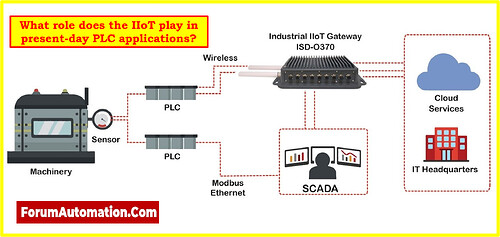

The Industrial Internet of Things (IIoT) is transforming Programmable Logic Controllers (PLCs) as it allows industries to exchange data with equipment in real-time. IIoT integration allows businesses to track operations in real-time for better maintenance anticipation and production optimization which enhances efficiency levels.

Key Benefits of IIoT in PLCs:

Real-time monitoring and control becomes achievable through consistent data collection which gives operators real-time process visibility while providing them with operational control.

Data analysis of sensors functions to reveal potential equipment issues before breakdowns take place thereby minimizing production stops.

The implementation of remote monitoring alongside automation systems creates safer operation conditions in dangerous environments.

The implementation of process optimization allows companies to cut waste and boost their productivity level.

The implementation of advanced data analytics reliance on large-scale data collection enables organizations to perform analysis of trends along with process enhancements.

Challenges in IIoT Adoption:

The integration of IIoT requires organizations to undergo costly and time-consuming processes for upgrading their traditional PLC systems.

Higher connectivity in industrial operations raises cybersecurity threats that need robust security systems for protection.

Standard protocols must be established to successfully connect IIoT solutions with current PLC systems.

The adoption of IIoT requires professionals who possess specialized knowledge about data management and system maintenance skills.

The analysis and processing of large data amounts must operate efficiently to achieve effective IIoT application.

The essential communication protocols which enable PLCs under IIoT include OPC UA, MQTT, CoAP, Modbus and Ethernet/IP.

Games between PLC devices and IIoT systems succeed due to the standardized protocols OPC UA, MQTT, CoAP, Modbus and Ethernet/IP.

The Role of Cloud Computing:

Cloud computing services improve IIoT-enabled PLC systems through their two key features of expandable data storage capabilities and enhanced security features.

Proper strategies and security measures in Industrial Internet of Things applied to PLC systems enable industries to reach better automation levels and efficiency while improving their digital competitiveness.

In today’s rapidly evolving industrial landscape, the Industrial Internet of Things (IIoT) is revolutionizing the way Programmable Logic Controllers (PLCs) operate. Traditionally, PLCs have been the backbone of industrial automation, controlling machinery and processes with precision. However, with the integration of IIoT, PLC applications have expanded beyond basic automation to real-time data analytics, predictive maintenance, and enhanced connectivity.

How IIoT Enhances PLC Applications

![]() Real-Time Data Collection & Remote Monitoring

IIoT-enabled PLCs gather data from multiple sensors across production lines, allowing operators to remotely monitor machine performance and make informed decisions without being on-site. This improves efficiency and reduces downtime.

Real-Time Data Collection & Remote Monitoring

IIoT-enabled PLCs gather data from multiple sensors across production lines, allowing operators to remotely monitor machine performance and make informed decisions without being on-site. This improves efficiency and reduces downtime.

![]() Predictive Maintenance & Reduced Downtime

By leveraging IIoT-powered predictive analytics, PLCs can anticipate equipment failures before they happen. This minimizes unexpected breakdowns, reduces maintenance costs, and extends the lifespan of industrial assets.

Predictive Maintenance & Reduced Downtime

By leveraging IIoT-powered predictive analytics, PLCs can anticipate equipment failures before they happen. This minimizes unexpected breakdowns, reduces maintenance costs, and extends the lifespan of industrial assets.

![]() Seamless Cloud & Edge Computing Integration

Modern PLCs can communicate with cloud platforms and edge computing devices, enabling real-time data processing, secure storage, and instant feedback loops. This connectivity enhances scalability and allows businesses to adapt to changing demands.

Seamless Cloud & Edge Computing Integration

Modern PLCs can communicate with cloud platforms and edge computing devices, enabling real-time data processing, secure storage, and instant feedback loops. This connectivity enhances scalability and allows businesses to adapt to changing demands.

![]() Improved Operational Efficiency & Productivity

IIoT-equipped PLCs provide insights into energy consumption, machine utilization, and process optimization. By analyzing these insights, manufacturers can identify inefficiencies, improve workflows, and reduce waste.

Improved Operational Efficiency & Productivity

IIoT-equipped PLCs provide insights into energy consumption, machine utilization, and process optimization. By analyzing these insights, manufacturers can identify inefficiencies, improve workflows, and reduce waste.

![]() Cybersecurity & Industrial Data Protection

With IIoT connectivity comes the need for enhanced cybersecurity. INS3 ensures that secure communication protocols and encrypted networks are implemented to protect sensitive industrial data from cyber threats.

Cybersecurity & Industrial Data Protection

With IIoT connectivity comes the need for enhanced cybersecurity. INS3 ensures that secure communication protocols and encrypted networks are implemented to protect sensitive industrial data from cyber threats.

At INS3, we specialize in integrating IIoT with PLC applications to help manufacturers optimize production, reduce downtime, and make data-driven decisions. Our MES, SCADA, and industrial analytics solutions enable businesses to harness the full potential of IIoT in industrial automation.

![]() Ready to transform your manufacturing process with IIoT-powered PLCs? Let INS3 help you unlock new levels of efficiency and automation. Contact us today!

Ready to transform your manufacturing process with IIoT-powered PLCs? Let INS3 help you unlock new levels of efficiency and automation. Contact us today!