What is the voltage tolerance of 24VDC?

What is the voltage tolerance of 24VDC?

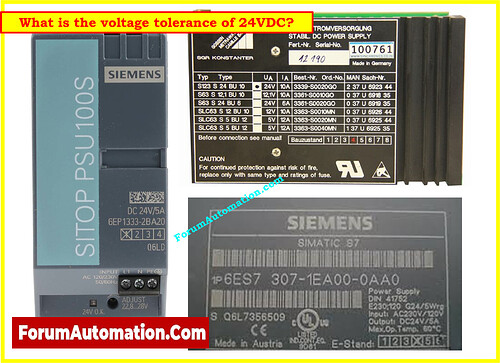

A frequent usage for the 24 VDC control supply in industrial automation is to power control circuits, such as servo motors with holding brakes. The normal voltage tolerance is ±5% (22.8 V to 25.2 V). However, when motors with holding brakes are involved, voltage planning needs to be more careful because of the length of the cables and the voltage loss.

When you connect a motor with a holding brake, the control voltage that needs to be at the motor’s brake connector (typically CN2) must be high enough to safely release the brake. The needed voltage changes based on the type of motor, the length of the motor cable, and the cross section of the conductor. The graph shows that motors like BMH/BSH…205 may need a control voltage close to 29 VDC when used with longer connections (up to 100 m or 328 feet). Lighter-duty motors, such …055 or …070, need lower voltage levels, although they still need to be above the nominal 24 V, especially for cables longer than 50 m.

The graph shows that different motors have distinct voltage rise curves as the wire length increases. This is because to resistive losses. The maximum supply voltage is shown by a dashed line at 29 VDC. The supply must always stay below this limit, but the voltage at the brake terminal must always be at least the minimum needed for the system to work properly.

24 VDC systems can handle ±5% of their normal load, but motors with holding brakes need higher voltage based on cable characteristics to keep the brakes from failing. For safe and reliable motor control, it is important to design the right size and voltage.