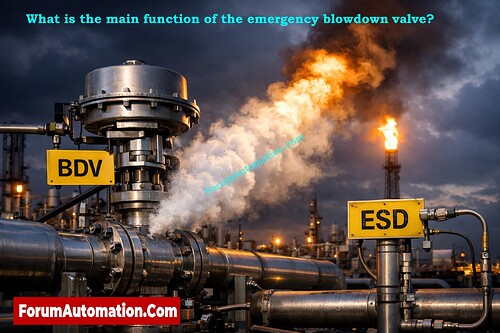

What is the main function of the emergency blowdown valve?

What is the main function of the emergency blowdown valve?

In process industries, the Emergency Blowdown Valve (BDV) is a very important safety valve that quickly lowers pressure and removes dangerous materials from vessels, pipelines, or process units when something goes wrong or there is an emergency. The main job of this system is to control depressurization, not normal flow. This is so that the system can be rendered safe should things like fire, equipment failure, loss of containment, or overpressure happen.

When the emergency shutdown (ESD) signal is turned on, the BDV opens by itself and sends the process fluid to a safe disposal system like a blowdown drum, flare system, or closed drain. This process greatly lowers the pressure inside the vessel and lessens the chance of it breaking, exploding, or making a fire worse. Shutdown valves stop the flow of entering water, while blowdown valves let out trapped merchandise. This makes both valves work together to keep things safe.

BDVs are built to meet high performance standards. They are the right size to get the depressurization time right while avoiding other problems, including liquid getting into flare systems. Pneumatic or hydraulic actuation is common, and there is a set fail-safe position. To manage high pressure, temperature, and corrosive fluids, the choice of materials, trim design, and discharge routing are all thoroughly thought out. It is important to test BDVs regularly since if one doesn’t open during an emergency, the whole safety strategy is useless.

Emergency blowdown valves are common on offshore platforms, in refineries, gas processing plants, and storage terminals where quickly lowering inventory can save lives, property, and the environment. This topic is getting a lot of attention in forums because BDV failures typically come up in incident investigations, thus it’s important to talk about how to keep them working properly.