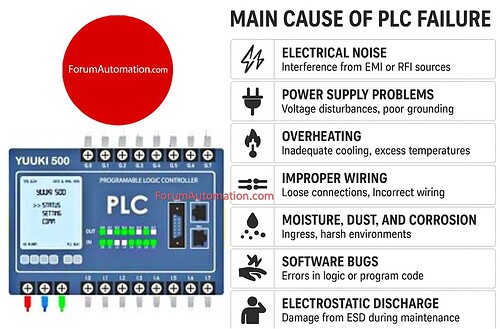

Top Causes of PLC Failures

1). Electrical Noise (EMI/RFI)

2). Power Supply Problems

3). Overheating

4). Improper Wiring (or) Loose Connections

5). Moisture, Dust & Corrosion

6). Software Bugs

7). Electrostatic Discharge (ESD)

8). Human Error

1). Electrical Noise (EMI/RFI)

Electronic noise (EMI/RFI) is one of the leading causes of failures in PLCs.

Induced by motors, drives, contactors (or) welding equipment that are located in close proximity

I/O signals can be disrupted, and PLC memory can be corrupted.

2). Power Supply Problems

Variations in voltage, surges, or inadequate grounding and grounding

Has the potential to result in logical mistakes (or) damage internal components

3). Overheating

As a result of inadequate ventilation, the accumulation of dust, or an elevated ambient temperature

Results in the deterioration of components or their shutdown

4). Improper Wiring (or) Loose Connections

Incorrect wiring or connections that are not secure

This results in sporadic malfunctions or problems with communication.

5). Moisture, Dust & Corrosion

Moisture, dust, and corrosion are included.

Particularly in case of unsealed panels or settings that are humid.

Can cause terminals to corrode or break short circuits.

6). Software Bugs

Bugs in the software or glitches in the firmware

Because of faults in the code or updates that are incompatible

7). Electrostatic Discharge (ESD)

(ESD) stands for electrostatic discharge.

It is possible for maintenance to cause harm to sensitive PLC components.

8). Human Error

The wrong wiring, the faulty ladder logic, the accidental deletion of memory, or the misuse of the device when troubleshooting

Prevention Tips

-

Utilize shielded cables and ensure adequate grounding to prevent any potential hazards.

-

To defend against surges, power conditioners should be installed.

-

Ensure that the control panels are kept clean, cold, and dry.

-

Ensure that routine maintenance & firmware updates are performed.

-

Maintain ESD-safe techniques and correct wiring at all times.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.