What is the difference between zero trim and sensor trim?

What is the Difference Between Zero Trim and Sensor Trim?

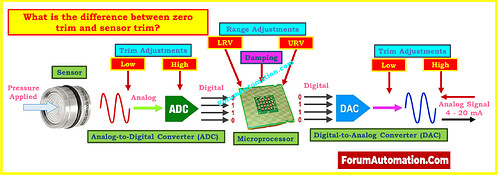

There are two different ways to calibrate pressure transmitters: zero trim and sensor trim. Each has its own job in keeping the measurements accurate.

Zero Trim

Purpose: Zero trim is a way to fix small offset problems in the transmitter output when no differential pressure is applied. It is done at one place. These mistakes are generally caused by: the mounting position, the process installation (for example, not properly equalizing the impulse lines), or the weather or mechanical factors.

Method:

With the transmitter’s process ports open to atmosphere or equalized, a zero pressure condition is applied. The transmitter is then adjusted to output the correct zero signal (e.g., 4mA for a 4–20mA output).

Example: A zero pressure condition is applied when the transmitter’s process ports are open to the atmosphere or equalized. Next, the transmitter is set up to send out the right zero signal, such 4mA for a 4–20mA output.

When to Use:

- After installation,

- After transmitter orientation changes,

- When offset is observed at zero pressure.

Sensor Trim

Purpose: Sensor trim is a two-point calibration that changes the transmitter’s internal analog-to-digital conversion technology. It fixes sensor errors over the whole range of measurements.

Method: Two reference pressures that are known (for example, 0% and 100% of span) are used. It is possible to calibrate the transmitter such that it gives accurate readings across its entire operational range.

Example: If a transmitter always reads 2% low at all pressures, a sensor trim will make sure that the complete pressure curve matches the real values.

When to Use:

- During initial commissioning,

- Periodic maintenance or re-calibration,

- When full-range accuracy is out of tolerance.

Key Differences at a Glance

| Feature | Zero Trim | Sensor Trim |

|---|---|---|

| Adjustment Type | Single-point | Two-point (Low and High) |

| Purpose | Corrects output offset | Calibrates full measurement range |

| Cause Addressed | Installation or mounting effects | Sensor accuracy errors |

| Complexity | Simple | More advanced |

| Usage Scenario | After installation or repositioning | For accurate calibration of full range |

| When you need to fix offsets or small zero shifts that are connected to installation, use zero trim. | ||

| Use sensor trim to calibrate the complete range, especially when you need to check or change the accuracy of the transmitter. | ||

| These trims work together to make sure that pressure transmitters work correctly and consistently in your process control system. |