What is the difference between rangeability and turndown ratio?

Rangeability vs Turndown Ratio selection and troubleshooting checklist

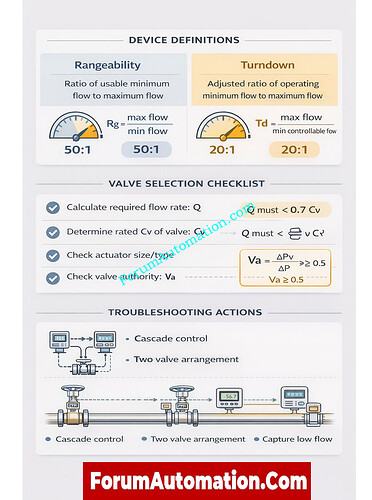

Rangeability and turndown ratio both talk about the useable span for instruments and valves, but they are used in various ways when choosing and using them. Rangeability usually means that a device can measure or regulate a value from high to low while keeping the same level of precision or repeatability. The turndown ratio tells you how long the device or control arrangement can work in the installed system while still fulfilling control goals.

Definitions:

-

Rangeability is the ratio of the highest measurable or controllable value to the lowest value at which the device still meets the required level of accuracy or repeatability. This is critical for flowmeters and transmitters.

-

The turndown ratio is the ratio between the highest capacity and the lowest flow or measurement that can be controlled in the installed setup. Turndown shows how different parts of the system work together, like the size of the actuator, the authority of the valve, and the behaviour of the loop.

Plant implications:

-

When choosing sensors, go with larger rangeability to prevent having to adjust the range often while making sure the accuracy is ensured across the desired band.

-

For control valves, use valve rangeability data to narrow down the trims, and then apply actuator sizing valve authority and loop simulation to make sure the turndown is correct.

-

For flowmeters, make sure that the meter rangeability covers both high and low flow circumstances in service.

Troubleshooting and selection checklist:

-

Write down the lowest and highest flows and pressures for the process.

-

Look at the needed turndown and the vendor’s stated rangeability and assured accuracy band.

-

If the needed turndown is more than what the vendor suggests, think about resizing the cascade control or using two valves.

-

Get low flow data during testing for tweaking and recording.