What is the difference between protection and interlock?

What is the difference between Protection and Interlock?

Protection and interlock are two important ideas in industrial automation and electrical/instrumentation systems. However, they have different goals and work at various points in the process of preventing risk.

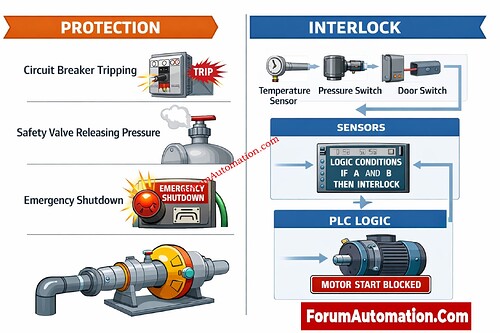

Protection is meant to keep things from becoming broken or hurt when something goes wrong or is wrong. It reacts when it sees a perilous situation. Circuit breakers, fuses, overload relays, pressure safety valves, and safety instrumented systems (SIS) are all common types of protection systems. Protection works on its own and frequently causes a trip, shutdown, or isolation to protect people, equipment, or the environment from damage. Safety standards like IEC, IEEE, and ISA often make protection systems non-negotiable. These systems focus on limiting the damage that can happen after a malfunction has already occurred.

Interlock, on the other hand, is a type of logic that stops things from happening. It makes sure that an operation can’t happen unless certain safe criteria are met first. Interlocks work before something dangerous happens. For instance, a pump might not start if the suction pressure is too low, or a motor might not run if the discharge valve is closed. Interlocks are often used in PLCs, DCS, or relay logic. They are utilized a lot to safeguard equipment, keep operations in order, and sequence processes.

The main difference In short:

- Protection → Reactive, based on faults, and damage control

- Interlock: Preventive, based on conditions, and avoiding faults

In short,

interlocks stop mistakes from happening.

Protection keeps damage to a minimum when things go wrong or mistakes are made.