What is the common problem in a control valve?

A control valve is one of the most important parts of a process control loop, yet it might have problems that make the system less reliable and slow down. Engineers can fix and keep valves working at their best by knowing about typical problems.

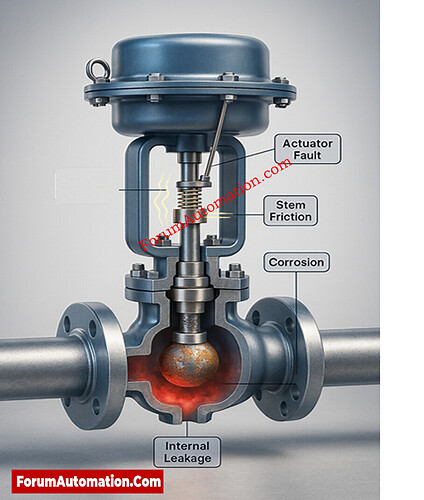

- Leakage Issues

When a valve is closed and fluid leaks through it, it’s called internal leakage. This can happen because the seats are worn down, the valve is eroded, or it wasn’t sealed properly. Damaged packing or gland seals are often the blame for external leaks. Both make it harder to control and raise safety issues.

- Sticking or Stiction

Friction, corrosion, dirt buildup, or tight packing can make valves stick. This makes it hard to control, cause oscillation, or move slowly. You may stop this by cleaning and oiling it regularly.

- Hunting or Instability

If the actuator or positioner isn’t set up correctly, the valve may move around its setpoint. This instability can cause too much wear, more maintenance, and less precise control.

- Actuator and Positioner Faults

A bad actuator diaphragm, a blocked air supply, or a positioner that isn’t set up correctly can all cause valves to work erratically. To keep everything running well, you need to check the air supply and calibrate the equipment every so often.

- Incorrect Sizing

Oversized valves usually only work well in a small range of control, while undersized ones have a hard time meeting process needs. During design, it is important to choose the right size and flow characteristics.

Some common problems with control valves are leaks, stiction, hunting, actuator malfunctions, and size issues. To keep valves working for a long time, they need to be properly calibrated and maintained on a regular basis.