What is the best way to test control valves?

A organized approach that includes preparation, inspection, functional tests, and conformity with international standards is the best way to test control valves. Control valves are very important for keeping process parameters like flow, pressure, and temperature under check. Regular testing and inspection are necessary, not optional, because any fault might lower efficiency, cause unscheduled downtime, or even pose safety risks.

The first step is to get ready by making sure the valve is isolated, depressurized, and that all the tools, like pressure gauges and position indicators, are on hand. Next, a visual inspection is done to look for evidence of corrosion, cracks, or wear on the valve body, stem, actuator, and bonnet. Next, an inside inspection may be done to check the condition of the trim, seals, and sitting surfaces.

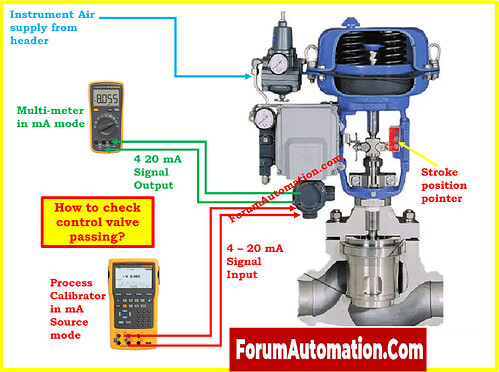

Testing for functionality is very important. This comprises leak testing to make sure the shutdown is tight, operational characteristic tests to check response time and flow control accuracy, and control signal testing to make sure the actuator responds correctly to orders. API 598, ISO 5208, and ANSI/FCI 70-2 are some of the standards that set the required leakage classes, pressure testing, and acceptance criteria. These standards make sure that all industries are equally reliable.

Documentation is just as crucial. Not only does recording test results, changes, and any corrective actions make sure you follow the rules, but it also gives you useful information for predictive maintenance.

The best way to check control valves is to use a thorough inspection and testing process that meets international standards. This makes sure that safety, efficiency, and long-term dependability are all at their best, which lowers costs over the life of the product.