What is SIF in process safety?

What is SIF in Process Safety? (Safety Instrumented Function)

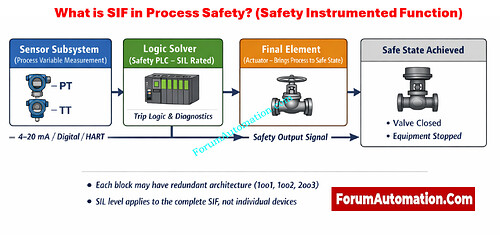

A Safety Instrumented Function (SIF) is an important safety feature that is used in process safety to stop risky events from happening or to return a process back to a safe state when something goes wrong. A SIF is a system that automatically finds dangerous situations and fixes them before an accident occurred.

A Safety Instrumented System (SIS) has a Safety Instrumented Function (SIF) built into it. The SIS is the whole safety system, although it is made up of several separate Safety Instrumented Functions. Each SIF is made to deal with one dangerous situation, such high pressure, high temperature, or low flow in a process plant.

Based on how much risk needs to be reduced, each SIF gets a Safety Integrity Level (SIL) of SIL 1, SIL 2, SIL 3, or SIL 4. IEC 61508 and IEC 61511 say how to figure out these SIL levels. Some of these ways are Risk Graph, Risk Matrix, and LOPA (Layer of Protection Analysis). SIL-1 has a minimum risk reduction factor (RRF) of 10 for low-demand applications that are typical in the process industry. SIL-2 has 100, while SIL-3 has 1000.

There are three basic parts to a Safety Instrumented Function:

-

Sensor subsystem (e.g., pressure, temperature, or level transmitters)

-

Logic solver subsystem (safety PLC)

-

Final element or actuator subsystem (e.g., shutdown valves, relays)

One essential thing to remember is that several SIFs can use the same sensor, logic solver, or actuator, but each SIF must have its own trip setpoints and SIL criteria. To make sure that process industries are safe and follow the rules, SIFs must be properly designed, tested, and maintained.

#SafetyInstrumentedFunction #SIF #ProcessSafety #FunctionalSafety #SIS #SIL #IEC61511 #IEC61508 #InstrumentationEngineering #ProcessIndustry #SafetyPLC #IndustrialSafety