What is minimum scan time in PLC?

What is Minimum Scan Time in PLC?

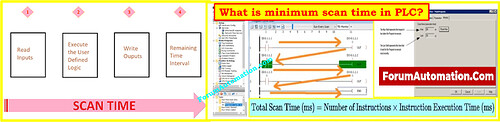

The minimum scan time in a PLC is the least amount of time it takes for the controller to finish one full cycle of work. This cycle includes:

- Reading all input signals,

- Executing the user logic (program),

- Updating all output signals.

For high-performance PLCs, this can be as little as 1 to 5 milliseconds. For smaller or general-purpose PLCs, it can be as much as 10 to 30 milliseconds or more. The shortest scan time, on the other hand, is only a theory. It requires that the program is very short, has not much I/O, and no extra communication time.

Practical Relevance of Minimum Scan Time

The minimum scan time is set by hardware and firmware limits, but in the real world, scan times are often longer because of:

- Program complexity (long or nested logic blocks),

- Large I/O count (both analog and digital),

- Network communications (Ethernet/IP, Profibus, Modbus),

- Interrupts or special function blocks (e.g., PID control, HMI updates).

Measuring Minimum Scan Time - Practical Test Method

The research study that is linked to this one (Alves & Morris, 2018) talks about a smart technique to find out the shortest scan time through experimentation.

- Writing a simple toggle logic in ladder programming.

- Physically looping back one digital output to a digital input (e.g., %QX0.0 to %IX0.2).

- The output toggles every scan, creating a square wave.

- Use an oscilloscope to measure the frequency f of this square wave.

Then apply the formula:

Scan Time=1/2f

This is because the output changes once for each scan, and a whole wave has two toggles: one from high to low and one from low to high.

Application Configuration Notes

- Set the minimum scan interval in the PLC settings (for example, the Res0 file) to T#1ms so that cycling can happen quickly.

- Set it to T#5ms or higher for delayed or normal scan tests.

- To save extra work, turn off any unneeded blocks, such as HMI updates or PID commands, throughout the test.

The minimal scan time is a hardware-defined number that shows how well a PLC works under the best possible settings. Engineers can do the following by knowing and monitoring it, even if it can’t generally be changed:

- Benchmark PLC responsiveness,

- Choose the right controller for real-time or fast-acting systems, and

- Optimize logic to stay within acceptable scan limits.

When making systems with tight control loops or timing that is crucial for safety, make sure that your average scan time is always much lower than the process’s needed update rate.