What is immersion length and insertion length in temperature measurement?

What is immersion length and insertion length in temperature measurement?

When measuring temperature, immersion length and insertion length are two key phrases that tell you how deep a temperature sensor or thermowell needs to be placed into the process fluid to get an accurate reading.

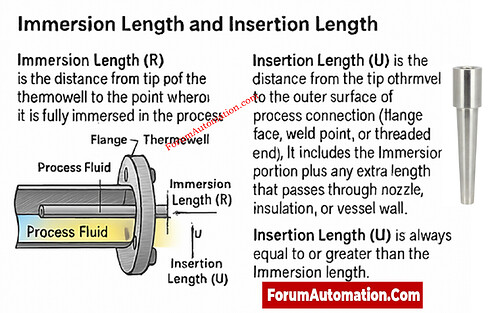

The immersion length (R) is the distance from the tip of the thermowell to the point where it is completely submerged in the process media. This is the part of the thermowell that really works with the fluid and measures its temperature. Correct immersion makes sure that heat is transferred correctly and reduces temperature mistakes caused by conduction or the environment. API RP 551 says that the immersion length should be at least 10 times the thermowell diameter or at least 2 inches for accurate measurement.

The insertion length (U) is the distance from the tip of the thermowell to the outer surface of the process connection, which could be the flange face, weld point, or threaded end. It includes the immersion part and any extra length that goes through the nozzle, insulation, or wall of the vessel. So, the insertion length is always the same as or longer than the immersion length.

To get accurate temperature readings and avoid failures caused by vibration, it is important to choose the right lengths for both. To make sure that temperature measurements are accurate and safe in industrial settings, these parameters should be set based on process design, pipe size, and relevant standards like ASME PTC 19.3 TW–2016.