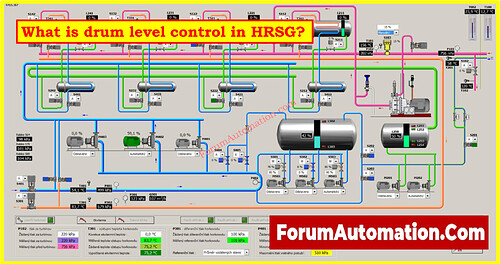

What is drum level control in HRSG?

Drum Level Control for HRSG, the Heat Recovery Steam Generator

In HRSG systems, drum level management is a vital ability to guarantee effective and safe boiler operation. A known reduction in drum water level may indicate boiler tubes, causing overheating and maybe damage. On the other hand, too high water level might lower steam quality by allowing moisture flow into the turbine and hence harm efficiency.

Systems of drum level control have several uses:

Maintaining water level to reasonable limits

Allow changes in the operator setpoint.

Correct for shrink and swell effects.

Turn on manual as well as automatic feedwater valve control.

Between modes, give smooth, bumpless transfer.

Show alarms, steam flow, valve position, drum level.

Drum level control methods come in four kinds:

Single-element control of feedwater uses just the drum level signal. For steady, low-capacity systems including single boilers and feedpumps, it’s basic and appropriate. It does not, however, pay for fast load variations brought about by shrink/swell effects.

Two-element control adds steam flow as a feedforward input to enhance load change response. Perfect for systems running continuously feedwater pressure, it still performs best using single boiler layouts.

For dynamic correction, three-element control combines feedwater, steam, and drum level inputs. Offering tighter control and faster response, it fits systems with changing loads, pressures, or multiple boilers or feedpumps.

Improved three-element control offers fallback depending on sensor availability. For better dependability and exact level control even under failure scenarios, it combines density compensation and redundancy.