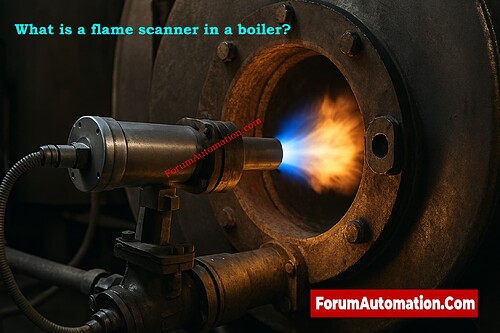

What is a flame scanner in a boiler?

A flame scanner is an important safety feature in a boiler that checks to see if there is a burner flame while it is running. Its major job is to make sure that the combustion is stable and to let the control system know right away if the flame goes out. This stops unburned fuel from building up in the furnace, which could cause an explosion or catastrophic damage to the equipment.

A flame scanner works by picking up the radiation that a flame gives off. It may be able to find ultraviolet (UV), infrared (IR), or both, depending on the technology. Because a flame gives out significant ultraviolet light when it starts, UV flame scanners work quickly. But sometimes they can be influenced by incorrect signals from things like welding. IR scanners can pick up on the infrared radiation and flicker pattern that hot combustion gasses make. This makes them more reliable in places that are dusty, smoky, or very hot. To make them more accurate and cut down on false alerts, many current flame scanners use both UV and IR sensors.

The scanner turns the observed radiation into an electrical signal that the boiler’s burner control system keeps an eye on. The system cuts off the fuel supply right away if it thinks the flame is weak, unsteady, or missing. This makes sure that the system works even if something goes wrong and keeps people and equipment safe. Flame scanners are used a lot in power plants, industrial boilers, furnaces, and process heaters. They keep an eye on things all the time to make sure that ignition is correct, combustion is stable, fuel is used efficiently, and the system shuts down safely when something goes wrong.