What is a DBV valve?

What is a DBV valve?

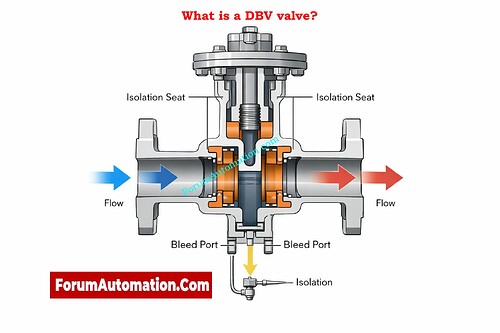

A DBV valve, which stands for “double block” or “double block and bleed,” is used to make pressured piping systems safer by providing a higher level of isolation. Its major job is to create two separate sealing barriers between the process fluid and the downstream side. There is also a bleed or vent point in the middle that lets you check that the shutdown is tight.

Both isolation barriers stay open during normal operation so that flow can happen. Both blocks are closed for maintenance or isolation, and the bleed port is opened to let out pressure that has built up between the two seals. If there is fluid or pressure at the bleed, it means that the seat is leaking right away. This gives operators a visual indication that the isolation is still intact. This feature makes DBV configurations far safer than using only one valve, especially in dangerous situations.

DBV valves are commonly employed in high-pressure utility systems, petrochemical industries, and oil and gas pipelines where hydrocarbons or poisonous fluids must not be released by mistake. Compact DBV designs make pipes less complicated, have fewer leak spots, and take up less space than standard multiple-valve systems. But it’s important to choose the right one seat design, cavity pressure behavior, and bleed routing must all work with the process fluid and the way the system works.

From a maintenance and permitting point of view, DBV systems make lockout/tagout procedures easier and provide workers more confidence. They also help the environment by lowering fugitive emissions. DBV issues do well in forum conversations because engineers typically talk about the best ways to vent safely, DBB versus DIB settings, and leakage classes.