What is a BMS system in a furnace?

What is a BMS system in a furnace?

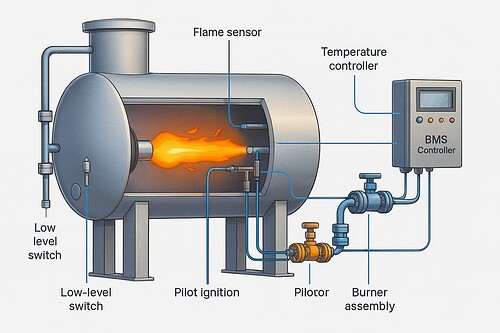

A Burner Management System (BMS) is a special safety and control system in a furnace that makes sure that burners used for heating in process facilities start up, run, and shut down safely. BMS systems can be found in things like reboilers, heater treaters, line heaters, and indirect-fired vessels.

What a BMS Does

A BMS keeps an eye on the burner’s working conditions all the time and makes sure that fuel is only delivered when the right circumstances for ignition and safe temperature are available. The key things it does are:

- Safe Ignition Control: Makes sure there is a pilot flame or employs electronic ignition to safely fire the burner.

- Fuel Safety Shutoff: Stops the flow of fuel automatically if the flame goes out. This keeps gas from building up and causing explosions.

- Temperature Monitoring: Uses thermostats or RTDs to keep an eye on the temperature of the vessel and keep it at the heating setpoint.

- High-temperature shutdown devices turn off the burner if the system becomes too hot.

- Monitoring Liquid Levels: A low-level switch in indirect heaters makes sure that the firetube is never exposed, which stops the tube from breaking.

Types of BMS

- Different kinds of BMS Manual BMS: Uses air-powered tools, a manual pilot ignition, and safety controls that work mechanically.

- Automated BMS: Uses electric ignition, RTDs, and electric burner valves to run more safely and efficiently while producing fewer emissions.

Why BMS Is Important

A furnace BMS keeps people and equipment safe by stopping backfires, gas leaks, overheating, and unsafe ways to start up. It also makes the gasoline more efficient and makes sure that the rules are followed.

BMS is the most important part of furnace safety. It makes sure that heating is reliable and that oil and gas process plants have as few operational risks as possible.