What is 10D and 5D in a flow meter?

What is 10D and 5D in a flow meter?

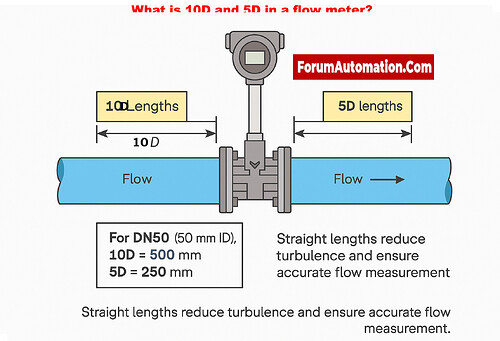

When measuring flow, especially with vortex flowmeters like the Yokogawa VY Series, the phrases 10D and 5D refer to the straight pipe lengths that are needed. These lengths are given as a multiple of the pipe’s inner diameter (D). These straight pipe portions are very important for getting accurate flow measurements since turbulence or uneven velocity distribution upstream or downstream can mess with the Kármán vortices that the flowmeter picks up. This is the pipe’s inner diameter, which is D. A DN50 pipe, for instance, has an inside diameter of about 50 mm. So, for DN50, a straight pipe length of 10D would be 10 × 50 mm = 500 mm, and a straight pipe length of 5D would be 5 × 50 mm = 250 mm. These straight lengths are meant to let the fluid flow settle down before it gets to the flowmeter. This reduces turbulence generated by upstream pipe fittings such bends, valves, reducers, or expanders. Turbulence can change the frequency of vortex shedding and make measurements less accurate.

For the VY Series vortex flowmeter, in real life: The requirements for upstream depend on the pipe elements: single bend: 10D; reducer: 5D; expander: 10D; and double bend not in the same plane: 20D.

The flowmeter design usually calls for a downstream demand of 5D.

Using the right straight lengths makes sure that the flow is stable, the readings are correct, and the installation is easy because there are no flow problems. Shorter straight pipes can lead to measuring mistakes, while longer pipes might not be needed until the facility needs them. In summary, 10D and 5D are the minimum straight lengths that vortex flowmeters need to work correctly in real-world piping settings. They are based on the pipe’s diameter.