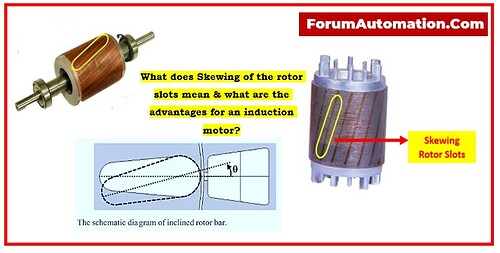

Skewing rotor slots is a method of design used in induction motors to enhance performance and lessen some adverse effects. In order to use this method, the rotor slots must be purposefully angled away from the rotor shaft’s axis.

-

The rotor slots in a conventional induction motor are ordinarily parallel to the rotor shaft’s axis. In contrast, these slots are tilted (or) skewed at a specific angle in a skewed rotor design.

-

Although the skew angle can change, it normally falls between one and three rotor slot pitches.

Advantages of Skewing Rotor Slots in the Induction Motors:

1). Reduced Torque Pulsations & Cogging Torque: Skewing the rotor slots serves to eliminate these two undesired traits of induction motors. Cogging torque may render the motor operating less efficient and less smooth, while torque pulsations can cause mechanical vibrations and noise. Skewing spreads out these effects, leading to a more consistent generation of torque.

2). Increased Starting Torque: Skewing can increase the motor’s starting torque. This is especially advantageous when the motor requires to start under demanding conditions with high inertia.

3). Enhanced Efficiency: Skewing can increase motor efficiency overall, particularly in transitory settings, by lowering torque pulsations and enhancing the motor’s starting torque.

4). Lowered Harmonic Content: Skewing reduces harmonics in air gap flux distribution, which minimizes magnetic noise and vibration in the motor. This is especially relevant in conditions that need silent operation.

5). Reduced Rotor Slot Effect: Skewing tends to decrease the influence of the rotor slot effects, such as magnetic locking & pulsing torques, which may develop because of to the interaction of rotor slots with stator windings.

6). Less Stress on Mechanical Components: The smoother functioning and less torque pulsations are able to lessen the stress and wear on the motor’s mechanical components, such as couplings and gearboxes.

7). Quieter and Smoother Operation: Skewing can provide a motor that runs more quietly and smoothly, which is beneficial in applications where vibration and noise levels must be kept to a minimum.

As a design technique, skewing the rotor slots of an induction motor has a number of advantages, including enhanced torque characteristics, less noise and vibration, improved starting performance, and generally smoother and more effective motor operation. Skewed rotor designs are particularly beneficial due to these advantages in a variety of industrial & commercial applications.