What does it mean if a valve is passing?

What Does It Mean If a Control Valve Is Passing?

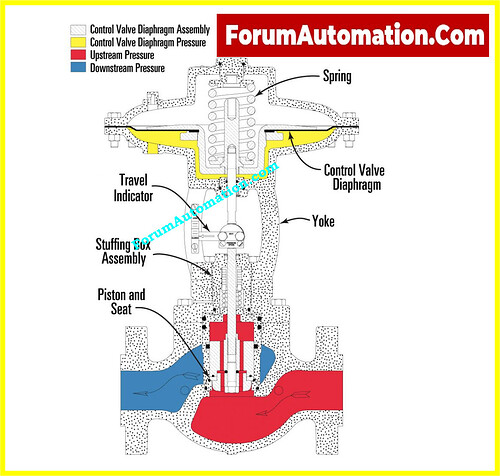

When a control valve is passing, it signifies that the valve is letting fluid seep through even when it is told to close all the way. The plug and seat, which are the interior sealing surfaces, are no longer making a tight seal, which is why this leak happens.

Control valves in process control systems use control signals to control the flow of fluids. When the valve gets a signal to close, such 0% or 4 mA, it should stop all flow. If it keeps leaking, the valve is “passing.”

Common Reasons for a Control Valve to Pass:

- Trim that is worn out or broken: The valve seat or plug might get worse from erosion, cavitation, or corrosion.

- Debris or fouling: Particles stuck between the sealing surfaces keep them from closing all the way.

- Seal or gasket failure: Soft sealing parts might break down because of age, pressure, or chemical attack.

- Incorrect actuator alignment or force: The actuator might not provide enough force or travel to fully close the valve.

What happens when a passing control valve:

- Loss of process control: The flow keeps going when it should stop, which makes the system less stable.

- Energy waste: heating, cooling, or pressure losses that aren’t needed.

- Problems with the quality of the product, especially in batch processes or applications with crucial flow.

- Risks to safety: systems that deal with steam, poisonous, or combustible materials.

How to Find It:

- Differential pressure checks

- Monitoring flow with a valve set at 0% command

- Detection by ultrasound or sound

- Testing for leaks when shutting down or doing maintenance

To make sure that process control is dependable and accurate, a passing control valve should be checked and, if necessary, fixed or replaced.