What are the three types of interlocks?

What are the three types of interlocks?

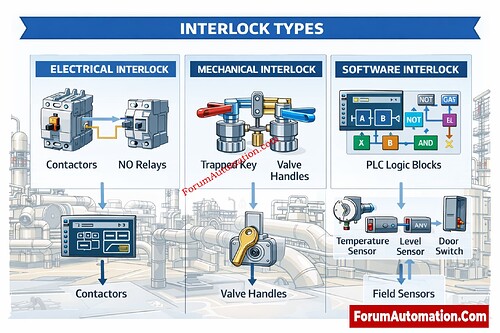

Interlocks are generally divided into three primary types in industrial automation and safety engineering. Each type has a distinct operational and safety purpose. Many PLC, DCS, and safety system design recommendations use these classifications as a reference.

1. Electrical Interlocks

Relays, contactors, limit switches, and auxiliary contacts are all examples of hardwired electrical circuits that electrical interlocks use. Motor control centers (MCCs), switchgear, and panel-based systems all use them a lot. For instance, an electrical interlocking system on a forward and reverse motor starter keeps both contactors from getting power at the same time. People realize that electrical interlocks are simple, dependable, and safe, especially in important situations.

2. Mechanical Interlocks

Mechanical interlocks stop an unsafe action by using mechanical means. They don’t depend on power or reasoning. Some examples are interlock systems with trapped keys, valve handle locks, and breaker interlock mechanisms. These are utilized a lot in switchyards, turbines, and high-pressure systems, which are all places where people shouldn’t be able to get to. Mechanical interlocks are very reliable because they don’t depend on software or power outage.

3. Software (Logical) Interlocks

PLC, DCS, or SCADA logic is used to make software interlocks. They use real-time process conditions like pressure, temperature, level, or flow to let or stop actions. For instance, a compressor start interlock may need the lubricating oil pressure, cooling water flow, and permission signals to be working properly. Software interlocks are the most common type employed in modern plants because they are flexible, quick to diagnose, and easy to change.