What are the three types of drum level control strategies?

What are the three types of drum level control strategies?

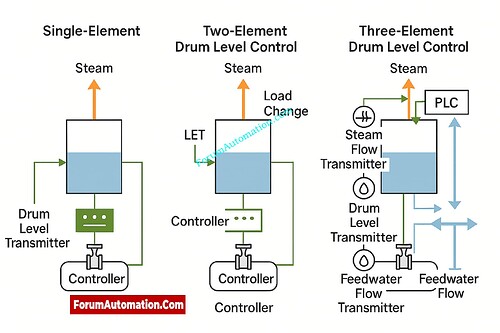

Drum level management is very important for safe, efficient, and reliable steam generation in boilers and HRSGs. There are three major ways to control drum level in process industries when the load changes.

1. Single-Element Drum Level Control

The only process variable in single-element control is the drum level measurement. The controller gets a signal from the drum level transmitter and then directly changes the feedwater control valve.

This plan is easy to follow and doesn’t cost much, so it’s good for low-pressure boilers that don’t need a lot of steam. However, it doesn’t work well when the load varies quickly because of shrink and swell effects, which cause the drum level to rise or fall without changing the mass. Because of this, single-element control can induce overcorrection, which makes the level unstable and causes alarms to go off often.

2. Two-Element Drum Level Control

Two-element control makes things more stable by employing two measurements: the level of the drum and the flow of steam. The steam flow signal is a feedforward input that lets the controller know when the demand for steam is likely to vary.

This method greatly lessens the effects of shrink and swell, and it is often employed in medium-pressure boilers. But it still implies that the flow of feedwater reacts correctly to the movement of the control valve, which may not be the case when there are problems with the feedwater or the pump.

3. Three-Element Drum Level Control

The most advanced technique is three-element control, which uses measurements of the drum level, steam flow, and feedwater flow. It uses both feedforward and cascade control to make sure that the flow of feedwater matches the flow of steam exactly while keeping the level of the drum proper.

This approach is very stable when the load changes quickly or the feedwater is disturbed. That’s why it’s the best choice for high-pressure and high-capacity boilers.

In short, the size of the boiler, the pressure it runs at, and how often the load changes all play a role in choosing between single-, two-, and three-element drum level control schemes. Three-element control is the safest and best-performing option.