What are the limitations of ultrasonic flow meter?

What are the Limitations of Ultrasonic Flow Meter?

People in the process industries like ultrasonic flow meters because they don’t get in the way, don’t cause a lot of pressure drop, and don’t need much maintenance. But before choosing ultrasonic flow meters for important flow measurement tasks, you need to know what they can’t do.

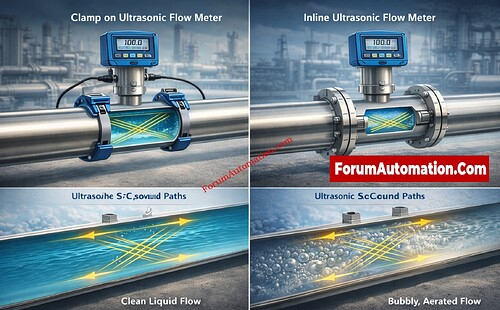

One big problem is that it is sensitive to the characteristics of the fluid. Ultrasonic flow meters use sound waves that travel through the fluid, therefore changes in temperature, density, and composition can make the measurements less accurate. When there are air bubbles, suspended particulates, or too much turbulence in a liquid, the signal gets weaker, which makes the measurements unreliable or wrong.

Another problem is that it needs to be installed. For ultrasonic flow meters to work properly, there must be enough straight pipe on both sides of the meter. Bad installation, pipe bends, valves, or flow disturbances near the meter can make performance a lot worse, especially with transit-time ultrasonic meters.

Ultrasonic flow meters also have trouble with very slow flow speeds. When the flow rate is low, the time difference between signals going upstream and downstream gets very small. This makes it harder to get accurate measurements. Because of this, they are not as good for uses that need accurate low-flow measurement.

Environmental and mechanical elements also have an effect. The type of pipe and the quality of the wall determine how well the signal travels. Ultrasonic signals can be weakened by pipes with thick walls, pipes with linings, or internal surfaces that are corroded. Also, clamp-on ultrasonic meters are usually less precise than inline kinds because the signal can get lost through the pipe wall.

In conclusion, ultrasonic flow meters work great for clean fluids and big pipes, but their limits should be carefully thought about. For ultrasonic flow measurement to be reliable, the right fluid conditions, installation methods, and application compatibility are all important.

Limited temperature measurement range: Ultrasonic flowmeters possess a restricted temperature measurement range, typically capable of measuring fluids below 200°C. This limitation restricts their application in high-temperature fluid measurement. Poor interference resistance: Ultrasonic flowmeters are susceptible to interference from bubbles, scaling, pump noise, and other extraneous ultrasonic sources, thereby compromising measurement accuracy. Such interference may become more pronounced in complex fluid environments. Installation uncertainties: Factors such as the installation position and angle of ultrasonic flowmeters can affect measurement results. Improper installation may lead to increased measurement errors. Therefore, careful calibration and commissioning are required during installation. Strict Straight Pipe Section Requirements: To ensure measurement accuracy, ultrasonic flow meters impose stringent requirements on the length of straight pipe sections at the installation point. Typically, a straight pipe section length of 10D to 20D (where D is the pipe’s internal diameter) is required upstream, with a specified distance from sound sources such as pumps. These requirements may limit their application in certain pipeline layouts.