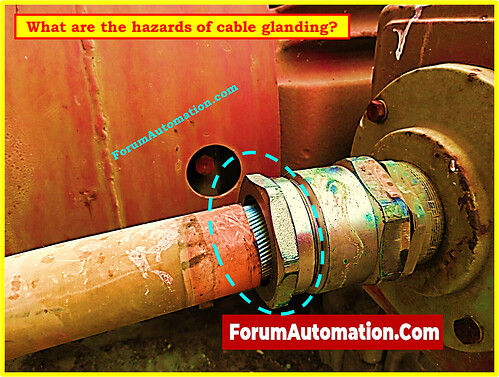

What are the hazards of cable glanding?

Hazards of Improper Cable Glanding

It may appear like a small part of an electrical system, but cable glanding is very important for safety, reliability, and compliance, especially in industrial facilities and dangerous areas. If you choose, install, or manage a cable gland badly, it could put the installation in considerable danger, such as electrical shock, fire, damage to equipment, or even explosions in areas where there are explosive gases.

One of the biggest risks is losing the right seal and mechanical retention. If the gland doesn’t hold the cable tightly, vibrations or pulling forces can loosen the terminations, which can cause sparking, short circuits, or live conductor exposure. In dangerous places like petrochemical factories, a broken seal can also let combustible gasses or dust into equipment enclosures, which can start a fire.

Another big risk is that moisture, dust, and caustic materials can get in. Cable glands can let in dirt and other things if they don’t have the right IP or Ex protection ratings. This can cause terminals to corrode, insulation to fail, and electrical systems to break down.

Using the wrong materials, like brass glands in places that are very corrosive without the right coating, can make things break down too soon. Not using the right gland type for armored and unarmored cables can also put earthing safety and continuity at risk.

Bad cable glanding is more than just a little mistake during installation; it might put people, processes, and assets at risk. Choosing, installing, and checking cable glands correctly are all important parts of any professional electrical or instrumentation job.