What are the digital outputs of PLC?

What are the digital outputs of PLC?

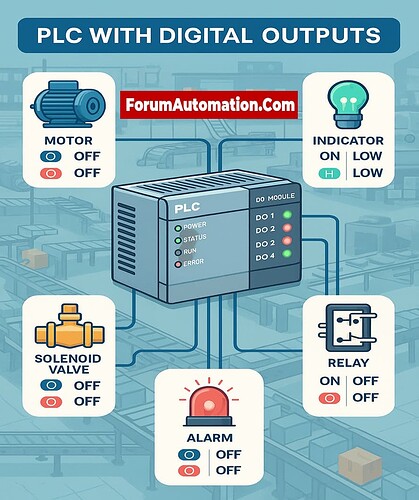

In a Programmable Logic Controller (PLC), digital outputs (DOs) are the channels through which the PLC transmits signals to control devices outside of the PLC in an industrial automation system. Digital outputs are like the “hands” of the PLC; they carry out commands based on the programmed logic. Digital inputs, on the other hand, get information from sensors and switches. These outputs are binary, which means they can be either ON or OFF, or HIGH or LOW.

A PLC’s digital output module connects to things like motors, solenoid valves, relays, indicator lights, or alarms. The PLC transmits an electrical signal over the digital output channel when it decides that a certain action needs to be taken, such as turning on a warning light or starting a conveyor belt. The output module then turns the associated device on or off, turning digital instructions into actions in the actual world. For instance, sending a signal to a motor starter will turn on the motor, and sending a signal to a valve actuator will open or close the valve.

Digital outputs are very important for industrial automation since they let you manage machines, processes, and safety systems very precisely. They are often used to regulate conveyor systems, pumps, and fans, manage robotic arms on assembly lines, and turn on sirens or warning lights in case of an emergency.

Digital outputs need to be set up and fixed carefully in addition to their operating duty. Engineers need to make sure that each output in the PLC program is connected to the right device and that the wiring and electrical integrity are correct. People regularly use diagnostic instruments like multimeters and oscilloscopes to check output signals and fix problems.

Digital outputs are the main way that a PLC interacts with the real world. They turn programmed logic into real-world actions that make automation more efficient and reliable.