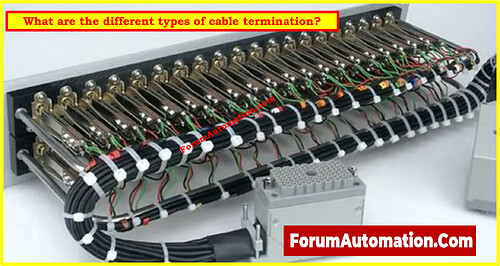

What are the different types of cable termination?

What are the different types of cable termination?

Cable terminations are very important for making sure that connections are dependable and that power or signals are transferred safely in electrical and networking applications. There are different kinds of terminations, and each one has its own strengths and uses.

Soldered Terminations: This approach employs solder to connect wires, making a strong, low-resistance connection. It is used a lot in electronics and PCB assemblies. It has great conductivity, but it might take a long time to work and is sensitive to heat.

Crimped Ends – This technology is often used in cars, planes, and power systems. It uses a crimping tool to compress a metal sleeve onto the conductor. It makes a connection that is gas-tight and resistant to vibration, which makes it very reliable for high-volume uses.

Compression Terminations: This method is often used in substations and high-voltage settings. It includes using bolts or screws to provide mechanical pressure to hold wires in place. They may be used again and again and are good for heavy-duty tasks, but they need to be done carefully and take time.

Wire Wrap Terminations: This method involves tightly wrapping a solid wire around a termination post. It is popular for prototyping and breadboards because it doesn’t need to be soldered and can be used again, although it can’t carry as much current.

Terminations for Insulation Displacement (IDT) IDTs are widely used in telecom and data cabling. They let conductors be placed directly into connectors with sharp blades that cut through insulation. They work quickly and well, however they don’t work as well with thick or stranded cables.

The correct termination depends on the application, the existing needs, and the environment where it will be installed. A termination that is done the same way every time and done well makes sure safety, performance, and long-term reliability.