What are the different types of automation in PLC?

What are the different types of automation in PLC?

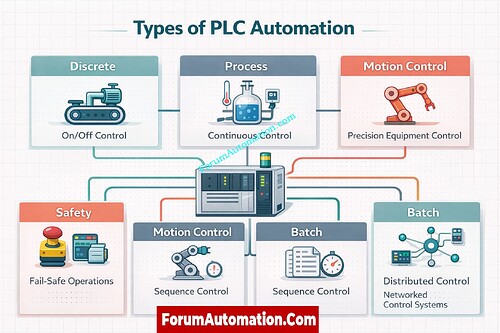

Programmable Logic Controllers (PLCs) may handle many types of automation, depending on how complicated the application is and what the industry needs. Discrete automation is used to turn relays, motors, and actuators on and off in packaging and assembly lines. Process or continuous automation uses PID and control modules to handle analogue loops like temperature, level, and flow in chemical or food plants. Motion control automation combines servo drives and stepper motors to position robots accurately. Safety automation incorporates safety features in CNC and conveyor systems. PLCs or safety-rated modules are used to set up emergency stops, safety interlocks, and SIL-certified functions. Batch automation uses ISA S88 patterns to control recipe-driven manufacturing with state machines that sequence transitions between steps. Sequential function automation (SFC) manages ordered logical steps with interlocks that are often used in filling and testing. Distributed control and remote I O designs use RTUs or remote I O to spread I O throughout big plants. Supervisory integration connects PLCs with SCADA historians, MES, or OPC UA for data logging, visualisation, and higher-level orchestration.

ladder logic, function block, structured text, and sequential function chart since they affect how each type of automation is set up. Some Examples of PLC automation types: discrete and process safety for motion control PLC batch control and SCADA integration. When choosing a PLC type, professionals should think about the number of I/O, cycle duration, and motion needs. SIL needs and the layout of the network.