What are the components of a boiler burner?

What are the components of a boiler burner?

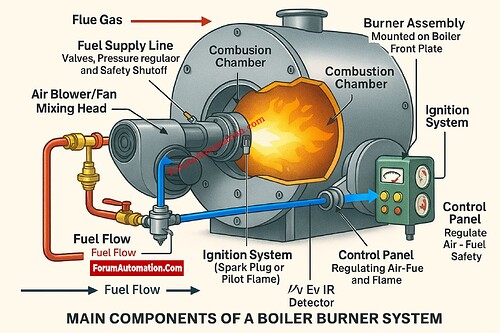

The boiler burner is an important part that starts and keeps the combustion process going, which makes heat that turns water into steam. It mixes air and fuel in the right amounts to make sure that combustion is as efficient as possible, which means that it produces the most heat with the least amount of pollution. The primary parts of a boiler burner work together to keep the flame steady, use less energy, and keep the burner safe.

Some of the most important parts are:

The fuel supply system brings fuel (natural gas, oil, or propane) to the burner. It has valves, pressure regulators, and safety shutoffs that control and stop the flow of fuel.

Air Supply System: Usually uses a fan or blower to give the combustion air it needs. For complete combustion, the air-to-fuel ratio must be right.

Mixing Head or Nozzle: This is where the air and fuel come together before they catch fire. The form, stability, and heat distribution of the flame depend on the nozzle design.

Ignition System: This includes spark electrodes or pilot burners that start combustion by lighting the fuel-air combination.

Flame Monitoring System: Uses flame scanners or UV/IR sensors to make sure the flame is there and not moving. The apparatus shuts off automatically if the flame goes out.

Control System: Changes the flow of fuel and air to match the demand for steam, which makes the system work better and safer.

The boiler burner is the most important part of the boiler’s heat generation process since it makes sure that combustion is complete, controlled, and safe.