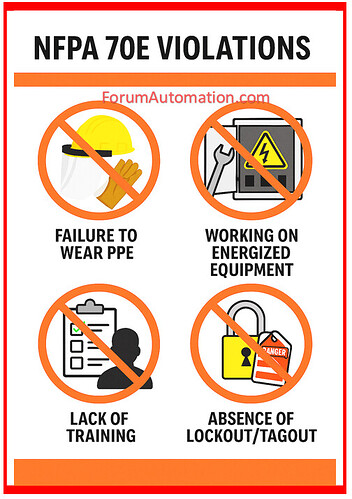

Common NFPA 70E Violations:

1). Failure to do an Arc Flash Risk Assessment

2). Inadequate or non-rated apparel in Arc Flash Zones

3). Working with Energized Equipment without Justification

4). Lack of Training

5). Inadequate (or) incomplete Lockout/Tagout (LOTO) Procedures

6). Unlabeled (or) Incorrectly Labeled Electrical Panels

7). Improper Maintenance of Electrical Equipment

8). Improper Utilization of Test Equipment

9). Inadequate Documentation

10). Unauthorized Persons in Electrical Areas

1). Failure to do an Arc Flash Risk Assessment

Not performing a proper arc flash analysis.

Using old (or) generic arc flash labels.

There is a lack of documentation regarding hazard boundaries & incident energy levels.

2). Inadequate or non-rated apparel in Arc Flash Zones

Avoid employing voltage-rated gloves, face shields, (or) balaclavas.

Using common apparel that can melt (or) ignite.

3). Working with Energized Equipment without Justification

Conducting maintenance (or) testing on active circuits without demonstrating that de-energization was not feasible.

There is no documented Energized Electrical Work Permit (EEWP).

4). Lack of Training

Employees have not been instructed on electrical risks, shock boundaries, or the proper use of personal protective equipment.

Training records are not maintained (or) updated at the required three-year interval.

5). Inadequate (or) incomplete Lockout/Tagout (LOTO) Procedures

Failure to isolate energy sources prior to starting work.

Incomplete or absent written LOTO plans.

Utilization of non-compliant locks and tags.

6). Unlabeled (or) Incorrectly Labeled Electrical Panels

Panels without arc flash markings or hazard warnings.

Voltage ratings and breaker schedules are incomplete.

7). Improper Maintenance of Electrical Equipment

Not maintaining breakers, switchgear, (or) transformers in accordance with manufacturer specifications.

Ignoring dust accumulation, corrosion, or loose connections, which enhance risk.

8). Improper Utilization of Test Equipment

Utilizing uncalibrated (or) non-rated meters to verify voltage.

To check the lack of electricity, skip the “live-dead-live” test method.

9). Inadequate Documentation

No Electrical Safety Program (ESP) is in existence.

There are no occupational safety plans or work justifications that are energized.

There are no records of training, audits, (or) PPE issue.

10). Unauthorized Persons in Electrical Areas

Non-qualified workers are permitted in restricted or electrified locations.

There are no signs or barriers surrounding live equipment.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.