What are the advantages of DCS over PLC?

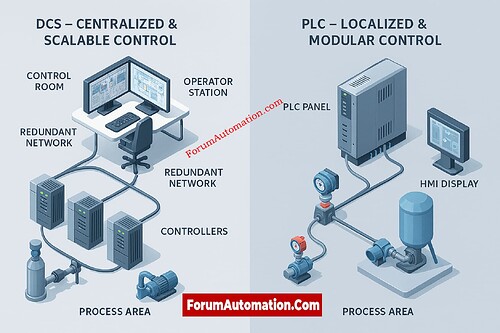

In large-scale process automation, a Distributed Control System (DCS) is far better than a Programmable Logic Controller (PLC). Both systems control and keep an eye on industrial operations, but they are different in size, design, and features.

- Scalability and System Integration

DCS systems are made to handle thousands of I/O points that are spread out over several process areas. They combine process control, monitoring, and data management into one system. PLCs are usually used for tiny, machine-specific tasks, although big operations may need more than one controller.

- Redundancy and Reliability

A DCS has built-in redundancy features like twin controllers, extra power supply, and networks that can handle faults. This makes sure that the system keeps working even if one part breaks. PLC systems can also have redundancy, although it usually costs more and takes more work to set up.

- Centralized Control and Monitoring

DCS gives operators a single place to watch and control the whole plant through centralized Human-Machine Interfaces (HMIs). PLC systems generally need SCADA or HMI software from outside the system to display data, which makes integration more difficult.

- Process-Oriented Control

DCS systems work best for operations that need precise analog control, trending, and logging of historical data, whether they are continuous or batch. They are popular in refineries, chemical facilities, and power plants. PLCs, on the other hand, are better for jobs that require discrete control, including packaging, assembling, or automating machines.

DCS is best for big, ongoing processes that need to be able to grow, be reliable, and have centralized control. PLCs are still the best choice for fast, discrete machine actions.