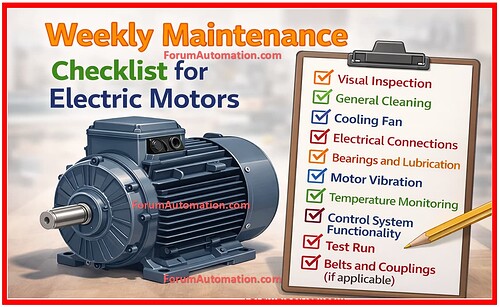

Weekly Maintenance Checklist for Electric Motors

To maintain the performance & longevity of electric motors conduct following weekly maintenance steps:

1). Visual Inspection

Check the motor and wiring for evidence of damage, wear or loose parts. Check for breaks, frayed wires and strange dis-colouration.

2). General Cleaning

Remove dust & debris from the motor and surrounding areas. Ensure that ventilation pathways are clear.

3). Cooling Fan

Ensure proper operation and clear obstacles.

4). Electrical Connections

Check all electrical connections for safety and corrosion.

Check that the coils are correctly connected and well-insulated.

5). Bearings and Lubrication

Check bearings in traditional motors (or) in extreme conditions.

Assure proper lubrication with the appropriate grease or oil.

6). Motor Vibration

Monitor the motor for unexpected vibrations during operation.

Excessive vibration can indicate misalignment, unbalance or bearing difficulties.

7). Temperature Monitoring

Monitor engine temperature to ensure it stays within manufacturer guidelines.

8). Control System Functionality

Ensure that the control system operates efficiently and responsively.

Inspect the buttons, switches & indicator lights.

9). Test Run

Run the motor for a short duration to evaluate its performance and response. Take note of any strange noises (or) abnormalities.

10). Belts & Couplings

Inspect it for corrosion, tension and alignment.

Replace or modify as needed.

Pro Recommended: Keep essential spare parts (e.g., bearings, belts, fuses) on hand to save downtime in case of failure.

Following these actions on a weekly basis will assist to keep electric motors running efficiently & extend their lifespan.

Checklist

Weekly Maintenance Checklist for Electric Motors.pdf (2.8 KB)