What is UV flame detector?

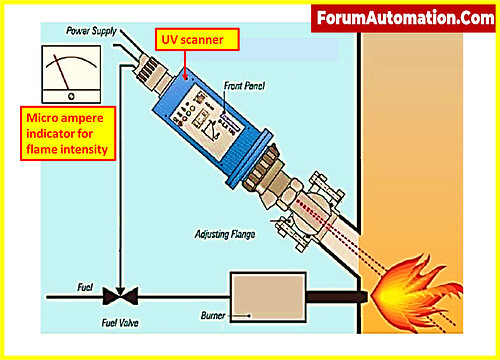

- A UV flame detector is a specialized instrument used in industrial settings to detect and monitor the presence of flames, particularly in combustion processes. It is also known as a UV flame scanner.

- It provides early detection of flames, which enables rapid response to possible fire threats, making it an essential component in both safety and process control systems.

- In order to determine the presence of a flame, this technique makes use of the detection of ultraviolet (UV) light that is released by the flame.

How Does a UV Flame Scanner Work?

- The idea that flames emit ultraviolet light is the foundation for the operation of a UV flame scanner. Many different chemical reactions emit energy in the form of light, which can include ultraviolet (UV) radiation, whenever there is a fire or a flame.

- The UV flame detector has a UV sensor or photodiode within it that is sensitive to UV radiation.

- This allows it to detect UV flames. This sensor will send a signal to the control system whenever it detects ultraviolet light that falls within a particular wavelength range.

- In most cases, the UV sensor will filter out other sources of light, such as natural sunlight or artificial lighting, to guarantee that the alarm or control reaction is only activated in response to the UV radiation that is released by a flame.

- Using this filtering helps to cut down on the number of false alarms.

What is the purpose of a flame scanner?

The Function of a Flame Scanner

A flame scanner’s principal function is to improve safety and efficiency in industrial processes that involve combustion. Among the most important goals and applications are:

Fire Detection

- Flame scanners are used to detect the existence of flames in industrial environments, which is crucial in preventing and responding to fires.

- They are common in power plants, refineries, chemical processing plants, and other facilities that use combustion processes.

Burner Management:

- Flame scanners play an important role in keeping a stable and efficient flame in industrial burners.

- They offer feedback to control systems to ensure the appropriate operation of burners, assisting in the optimization of fuel usage and the reduction of pollutants.

Safety Systems:

- Safety systems use flame scanners to shut down equipment or activate fire suppression procedures in the case of a flame-out or abnormal combustion conditions.

- This protects both employees and equipment.

Process Control:

- Flame scanners can help with process control in some circumstances by ensuring the presence of a continuous flame, which is critical for preserving product quality and process stability.

Environmental Compliance:

- Monitoring flames may assist with environmental compliance by assuring efficient combustion, limiting emissions, and eliminating uncontrolled combustion events that release pollutants.

What is the range of a flame detector?

- A flame detector’s range is determined by several elements, including the type of sensor, its sensitivity, and the properties of the flame. UV flame detectors typically have a range of several meters.

- This range, however, can vary depending on the specific application and detector design.

- Multiple UV flame detectors may be strategically arranged to ensure comprehensive coverage in larger industrial processes with larger burners or combustion chambers. The range can also be modified based on the detector’s sensitivity settings to meet the needs of the application.

- UV flame detectors or scanners are critical safety and control devices in industrial environments where combustion processes occur.

- They detect UV light released by flames and can be used for fire detection, burner control, safety, and environmental compliance.

- A flame detector’s range varies, but it normally covers several meters and is adjustable to specific application needs.

- These devices are vital in protecting industrial facilities, employees, and the environment from the dangers of uncontrolled flames and fires.