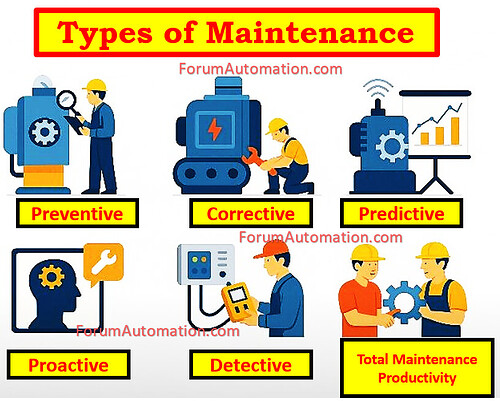

Types of Maintenance

What is Maintenance?

Maintenance is one of the most important areas for ensuring the continuity, safety & efficiency of industrial processes, buildings and other technological systems.

Types of Maintenance

The different types of maintenance are:

1). Corrective Maintenance

3). Predictive Maintenance

4). Detective Maintenance

5). Proactive Maintenance

1). Corrective Maintenance

Equipment breakdowns might be intentional or spontaneous.

Ideal for non-critical systems (or) when downtime is minimal.

2). Preventive Maintenance

Scheduled at regular intervals based on time (or) equipment utilization.

It includes scheduled inspections, adjustments & replacements to prevent failures.

Concentrate on reducing downtime & extending asset life.

3). Predictive Maintenance

Continuous monitoring of conditions, such as vibration, temperature, and noise, is used.

It use technology to anticipate breakdowns.

It necessitates data analysis & diagnostic tools.

4). Detective Maintenance

Detect hidden holes in security & protection systems.

Very common in circumstances wherein the failure is not immediately apparent but can result in dangers.

5). Proactive Maintenance

This method prioritizes identifying and resolving the root cause of errors, frequently in conjunction with reliability technologies like RCM. It needs a culture of continual improvement and a thorough examination of failure modes.

In conclusion, selecting the appropriate solution for every component of machinery is important for balancing cost, availability & safety. Maintenance advancement in a corporation requires an understanding that there is no single optimal technique, but rather a smart combination of them.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.