The precise installation of a thermowell is critical for accurate temperature measurement and the protection of both the sensor and the process. Thermowells are often used to protect temperature sensors from harsh process conditions in a variety of industrial applications, including chemical processing, HVAC systems, and power plants.

Where should I install my thermowell? A guide for best practices

Consider the following principles for thermowell installation best practices:

Choosing the Best Thermowell:

Begin by selecting a thermowell that is appropriate for your purpose. Consider the process fluid’s corrosiveness, temperature range, and pressure. Check that the thermowell material is suitable with the fluid and the environment around it.

Suitable Location:

The thermowell’s location within the process piping is crucial. It should be put at a location where it accurately shows the process fluid’s temperature. Avoid areas where there are considerable flow disruptions, dead zones, or low flow rates, as they can cause erroneous readings.

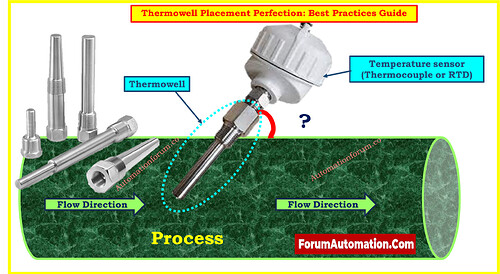

Depth of Insertion:

The thermowell’s insertion depth is critical. It should be long enough to completely immerse the temperature sensor (often a thermometer or thermocouple) in the process fluid. This guarantees that the temperature is accurately measured. For the proper insertion length, see industry standards or manufacturer recommendations.

Orientation:

Place the thermowell in the proper orientation. It should be positioned vertically or at the prescribed angle, especially in applications where stratification or temperature gradients may occur. Thermal stratification causes inaccurate temperature measurements, which can be avoided with proper orientation.

Immersion Depth:

Ascertain that the temperature sensor is completely immersed in the thermowell. Inadequate immersion can result in inaccurate readings. The tip of the sensor should be in the middle of the thermowell and should not touch its walls.

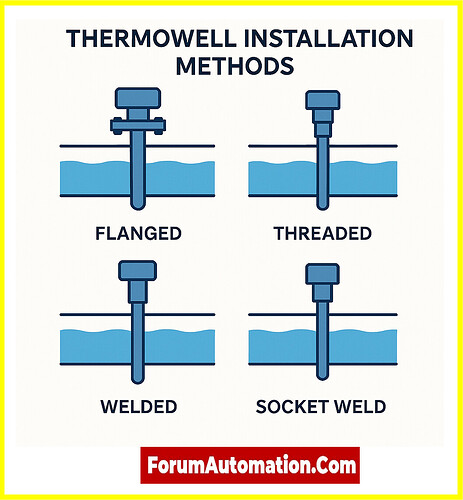

Tightening and sealing:

Sealing and tightening are essential for preventing leaks and maintaining process integrity. Use the prescribed sealing materials and torque parameters from the thermowell manufacturer. Overtightening might cause thermowell damage or stress spots.

Heat Tracing and Insulation:

Consider whether your application requires insulation or heat tracing. Insulation or heat tracing can help preserve accurate temperature measurements and protect the thermowell in procedures with significant temperature changes or when freezing is a concern.

Compatibility of Materials:

Check that the thermowell material is suitable with the process fluid and the surrounding environment. Use corrosion- and wear-resistant materials in corrosive or abrasive conditions, such as stainless steel or exotic alloys.

Calibration and testing:

Calibrate and test the temperature sensor and thermowell assembly on a regular basis. This guarantees that your measurements are consistent throughout time. Calibrations should be carried out by trained individuals using traceable standards.

Inspection and maintenance:

Create a thermowell maintenance and inspection schedule. Inspect them on a regular basis for symptoms of corrosion, erosion, or mechanical damage. To avoid compromising measurement accuracy, replace any broken thermowells as soon as possible.

Standards compliance:

For thermowell installation and maintenance, adhere to industry norms and guidelines. ASME PTC 19.3 and ISA-75.19.01, for example, contain detailed guidance for recommended practices.

Considerations for Safety:

When installing thermowells, put safety first. Ensure that the installation process adheres to safety rules and that workers have adequate training to use the equipment.