Why is electromagnetic flowmeter grounding important?

- Grounding is a key aspect of electromagnetic flowmeters (EMFs) that is often forgotten but is essential to their accurate and reliable operation.

- EMFs are often used to measure the flow of conductive liquids in industries like water treatment, chemical processing, and the control of wastewater.

- To understand why grounding is so important in electromagnetic flowmeters, we need to look at how they work and what problems they might face.

- Faraday’s law of electromagnetic induction is the basis for how an electromagnetic flowmeter works.

- It depends on how a magnetic field interacts with a fluid that is moving through a pipe or tube.

- When an electrically conductive fluid runs through the meter’s pipe, it cuts through the magnetic field generated by the coils in the meter.

- This causes a voltage that is proportional to the speed of the fluid. This voltage is collected and used to figure out the flow rate.

- Grounding is a very important part of making sure that this voltage information is accurate and stable.

Here are a few of the most important reasons why electromagnetic flowmeters need to be grounded:

Electrical Noise Reduction:

Electrical noise is common in workplaces, and it can interfere with the weak voltage signs that EMFs carry out. Grounding helps electrical interference to dissipate and move away from the flowmeter. This keeps measurements accurate and keeps wrong results from occurring.

Safety:

Grounding serves as a safeguard by dissipating excess electrical charges or potential differences. This reduces the risk of electrical shocks and other hazards to both personnel and equipment. EMF can become a source of electrical risk if not properly grounded.

Reference Point:

Grounding creates a steady reference point for the electromagnetic flowmeter’s electronics. This reference is critical for proper measurements and calibration. Without it, the system may drift or create inconsistencies.

Ground Loop Prevention:

Grounding helps in the prevention of ground loops, which arise when several channels for current flow exist between distinct pieces of equipment. Ground loops can introduce undesired signals into the EMF measurement circuitry, leading to errors.

Corrosion Prevention:

The conductive fluids being tested in many industrial processes can be corrosive. Proper grounding can assist prevent corrosion of the flowmeter’s electrodes or coils caused by stray electrical currents or potential variations.

Regulatory Compliance:

For precise flow measurement, several businesses have stringent regulatory requirements. Proper grounding guarantees that the EMF complies with these regulatory regulations, avoiding significant legal and financial consequences.

Equipment Protection:

Grounding protects the flowmeter and its related electronics from transient voltage spikes or surges that can damage sensitive components and cause costly downtime.

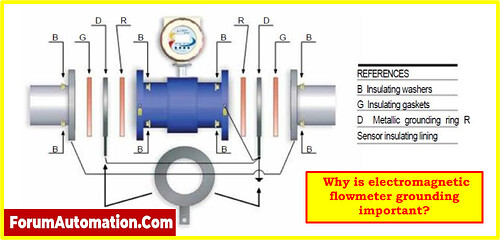

To achieve effective grounding in electromagnetic flowmeters, several practices should be followed:

Ground Electrodes:

The flowmeter should have dedicated grounding electrodes or grounding rings installed to establish a reliable connection with the ground.

Low-Resistance Path:

Ensure that the grounding path has a low electrical resistance to enable for effective charge dissipation. Typically, conductive materials like as copper or aluminum are used.

Proper Installation:

Follow manufacturer guidelines for proper installation and grounding procedures. This includes securely connecting the flowmeter to the grounding system and ensuring that all electrical connections are tight and corrosion-free.

Regular Maintenance:

Inspect and maintain the grounding system on a regular basis to ensure its continuous efficacy. Connections can corrode or weaken over time, resulting in inadequate grounding.

Finally, grounding is an important part of electromagnetic flowmeter operation. It ensures measurement accuracy, safety, and regulatory compliance in industrial applications. Proper grounding techniques protect the flowmeter from electrical interference, keep its reference point stable, and avoid problems like ground loops and corrosion. As a result, it should never be disregarded while designing, installing, and maintaining electromagnetic flowmeter systems.