What is Process control network?

- A sort of computer network called a process control network (PCN) is used in industrial and manufacturing settings to monitor, regulate, and improve the performance of complicated processes or systems. Industrial automation, production, chemical processing, oil and gas refining, electricity production, and other industrial processes are some examples of these processes.

- The PCN depends on communication networks to enable the transfer of information and orders between the different parts of the system.

- Local area networks (LANs), wide area networks (WANs), and other types of networks can be a part of these networks, which can be wired or wireless.

- Since real-time monitoring and control are essential to ensuring the secure and effective functioning of industrial processes.

- Security is a major problem in PCNs since any disruption or unauthorized access to the system can have detrimental effects on safety, the environment, and the economy. In order to guard against cyber threats and guarantee the integrity and confidentiality of the data transmitted within the network, PCNs often have strong security measures in place, such as firewalls, intrusion detection systems, access control mechanisms, and encryption.

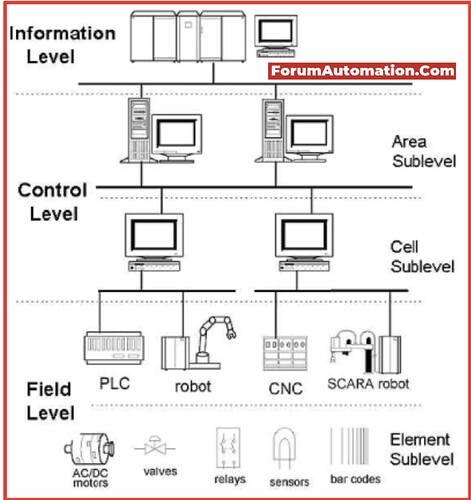

- The PCN typically comprises of a mix of hardware and software elements, such as networked computers, sensors, actuators, and controllers.

- Sensors collect information from several process locations, including temperature, pressure, flow rate, and other pertinent characteristics.

- The controllers receive this data and employ logic and algorithms to assess it and make decisions based on it.

- In order to change the process parameters and produce the required results, actuators are used to control the process’s physical components, such as valves, motors, and pumps.

- Process control networks provide effective and automated control of complex processes, increase operational efficiency, and improve safety and dependability, which all contribute to their vital role in modern industrial operations.

- With technological advancements like the Internet of Things (IoT), cloud computing, and artificial intelligence (AI), which are rapidly being incorporated into industrial contexts to provide more complex and advanced process management capabilities, they continue to develop.

Describe the Domain controller

- An administrator known as a domain controller serves as the central authority for managing user accounts, groups, computer accounts, and other network resources in a Windows domain, a type of network organization used by Windows Server operating systems.

- Domain controllers are a vital component of Windows-based networks and play a key role in handling user authentication, security, and resource access.

- To ensure high availability of domain services, multiple domain controllers can be placed in a domain for redundancy and fault tolerance. DC’s are therefore necessary for preserving the confidentiality and integrity of a Windows domain network.

How does a domain controller function in a process control network?

- A PCN is a network that has been created expressly for regulating and observing industrial activities, including manufacturing, the production of oil and gas, and the generation of electricity.

- The precise function of a domain controller in a PCN can change based on the industrial automation system’s architecture, design, and requirements. To build and deploy a PCN that meets the unique requirements of the industrial process being controlled, Hence, DC’s can be extremely important in controlling and protecting the PCN infrastructure to guarantee the secure and dependable operation of industrial automation systems.

In order to manage and automate industrial processes, it often consists of interconnected control systems, sensors, actuators, and other devices. The following are some potential duties for a domain controller in a PCN:

1. User authentication A domain controller in a PCN may be in charge of authenticating users who try to access the network or the industrial automation system, similar to its function in a standard Windows domain

2. Access control To control who has access to various components of the industrial automation system, such as certain devices or control functions, a domain controller in a PCN may enforce access control policies.

3. System configuration and management In a PCN, a domain controller may be in charge of overseeing the settings and configuration of industrial control devices including programmable logic controllers (PLCs), distributed control systems (DCS), and human-machine interfaces (HMIs).

4. Security management A domain controller in a PCN may be involved in managing the industrial automation system’s security, which includes putting security policies into place, keeping an eye out for security lapses, and managing security certificates for secure device connection.

5. Redundancy and fault tolerance A domain controller in a PCN may be deployed in redundant and fault-tolerant configurations, similar to its function in a traditional Windows domain, to ensure high availability of domain services, which can be crucial in industrial automation systems where uptime and dependability are important.