Controlling the forward and backward operation of a three-phase induction motor is a typical need in industrial automation. Typically, this is accomplished by relay logic involving contactors, push buttons & interlocks.

However, using a PLC (Programmable Logic Controller) with TIA Portal software improves the process’s safety, efficiency, and ease of troubleshooting.

This post describes the ladder logic program created in TIA Portal for safe forward and backward operation of an induction motor, which includes

- Interlocks,

- Stop logic and

- Overload protection.

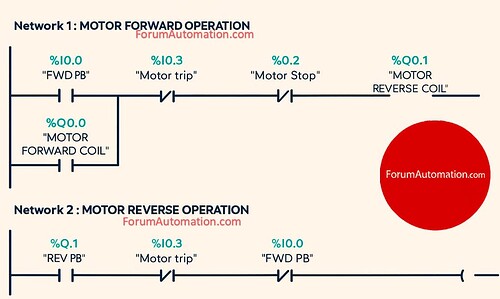

Forward logic (Network 1)

Input: Forward Push Button (FWD PB → I0.0).

Output: Forward Contactor Coil (Q0.0).

Working:

When the Forward PB (I0.0) is pushed, the Forward Contactor (Q0.0) is turned on.

Q0.0’s latching contact ensures that the motor continues to run forward even after the PB is released.

An interlock contact (NC of Q0.1) is connected in series to keep the forward contactor from going on if the reverse contactor is already active.

Reverse logic (Network 2)

Input: Reverse Push Button (REV PB → I0.2).

Output: Reverse Contactor Coil (Q0.1)

Working:

When the Reverse PB (I0.2) is pushed, the Reverse Contactor (Q0.1) is turned on.

Q0.1’s latching contact maintains the motor running in reverse till stopped.

An interlock contact (NC = Q0.0) makes sure the reverse contactor cannot switch on while the forward contactor is operating.

Interlocking for Safety

Cross Interlocking:

The forward & reverse networks are mutually interconnected.

This prohibits both contactors (Q0.0 & Q0.1) from energizing simultaneously.

Without this safety measure, pushing both push buttons could result in a short circuit (or) mechanical damage to the motor.

Stop and Safety Features

The STOP Push Button (PB → I0.1) is connected in series in both forward & reverse networks.

Overload Relay (OLR → I0.3) is connected in series with both networks.

If an overload occurs, the OLR trips, disconnecting the control circuit and stopping the motor.

This provides motor protection in opposition to overcurrent & overheating.

Advantages of PLC-Based Control Over Relay Logic

- Modify logic without rewiring the hardware.

- PLC enables real-time monitoring & fault detection.

- Cross-interlocking ensures safe operation.

- Fewer moving parts than relay-based circuits.

- Compatible with SCADA/HMI for enhanced control and visualization.

This TIA Portal PLC-based ladder logic software controls a 3-phase induction motor in both forward and reverse directions, ensuring its safety, efficiency, and dependability.

Compared to traditional relay circuits, the PLC method provides superior protection, flexibility & industrial-grade automation.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.