Motor Starter Coordination

When it regards motor starters , choosing the appropriate coordination type is essential for both safety and efficiency.

Here is a simple breakdown:

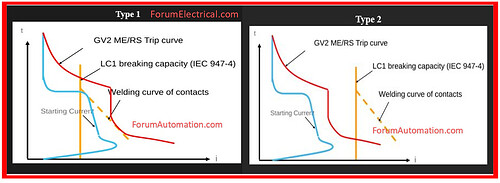

Type 1 Coordination

Protects against short circuits, but may cause irreversible damage following a malfunction (e.g., melted contacts or wrecked overload relays).

Ideal for the low-risk environments, but may require downtime for repairs.

Type 2 Coordination

Provides protection while remaining useful after a defect, generally requiring only modest modifications (e.g., separating tack-welded connections).

Recommended for important applications to reduce downtime and preserve service.

Why It Matters?

Selecting between Type 1 & Type 2 can affect your operation’s safety and efficiency.

Type 2 protects individuals and installations, lowering costs and downtime.

Components Matter:

In order to achieve successful Type 2 coordination, make sure that the system includes certified components (such as circuit breakers & thermal overloads) that fulfill IEC standards.

Choose wisely to improve operating dependability and safety.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.