Industrial Motor Control Using CJX1 Contactors and JD-5 Motor Protection

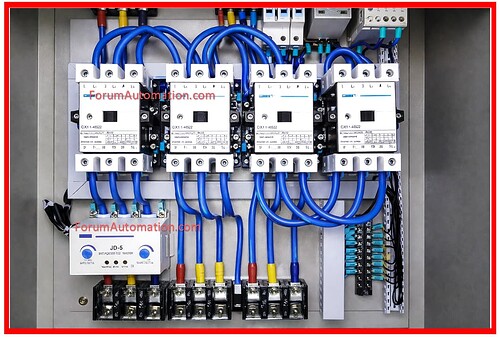

This system is a heavy-duty star-delta starting panel designed to provide dependable & energy-efficient control of 3 phase induction motors.

The panel’s integration of CJX1 series AC contactors with a JD-5 intelligent motor protection relay provides controlled motor starting, decreased electrical stress and comprehensive protection in industrial operating conditions.

CJX1-4522 AC Contactors: Power Switching and Control

CJX1-4522 AC contactors are high-capacity electromagnetic switching devices rated at 45 A & up to 660 V AC designed primarily for medium-power three-phase motors.

In a star-delta arrangement, three contactors are used: primary (line), star & delta contactor.

During startup, the main & star contactors activate to link the motor windings in star configuration decreasing the applied phase voltage.

Following a predetermined interval, the star contactor disengages & the delta contactor activates reuniting the motor windings in delta for regular rated operation.

This sequence considerably minimizes starting current & mechanical stress making it simple for motors rated between 22 and 30 kW which are often used in pumps, compressors and conveyor systems.

JD-5 Integrated Motor Protection Relay: Intelligent Safety Layer

The JD-5 motor protection relay protects against electrical overload detects phase failure monitors phase imbalance and signals a short circuit fault.

It continuously monitors motor current & thermal parameters while in operation.

When the relay detects abnormal conditions such as overcurrent, phase loss (or) prolonged thermal stress it trips & opens its auxiliary contact, de-energizing the contactor coil & isolating the motor.

This proactive protection avoids winding damage reduces unplanned downtime and assures compliance with IEC motor protection regulations making it appropriate for tough industrial applications.

Wiring Diagram with Control Logic

The panel uses a structured wiring technique, with THHN-insulated wires utilized for power and control circuits to provide thermal & electrical reliability.

Electrical & mechanical interlocking across the star & delta contactors prohibits simultaneous operation hence eliminating the risk of short circuits.

A dedicated star-delta timer relay regulates the transition period which is normally set between 5 & 10 seconds to allow the motor to attain a sufficient speed before transitioning to delta mode.

This control logic allows for smooth, automatic motor starting in applications such as HVAC systems, manufacturing plants & water treatment facilities.

DIN Rail Assembly & Modular Construction

All components are installed on conventional DIN rails with modular devices from established suppliers.

This modular design facilitates installation, improves panel organization and facilitates maintenance and also troubleshooting and future system expansion.

The standardized layout minimizes downtime and enables scalable industrial automation systems.

Engineering Significance of Star–Delta Motor Control

The star-delta starter is still a popular and reliable method for decreasing inrush current, limiting voltage drops & reducing mechanical shock during motor beginning.

This system achieves exceptional operational reliability, fault tolerance & energy efficiency by integrating durable contactors with intelligent protective relays.

Such designs are essential in modern electrical engineering, especially in applications where long motor life, system safety & regulatory compliance are essential for long-term industrial operations.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.