What is a PC?

- PC is an abbreviation of a Personal Computer.

- A Personal Computer is a digital computer intended for personal use

- Generally, this Personal Computer assembly includes a

Central Processing Unit (CPU), for arithmetic & logic operations

- Memory units such as Main Memory, Digital Random-Access Memory, & Auxiliary Memory like Magnetic Hard Disks, & Special Optical Compact Discs like CD/DVD-ROMs.

- Various Peripheral Devices like Display Units called Monitor Screens, keyboards, mice, and printers.

What is PLC?

- A PLC is an abbreviation for a Programming Logic Controller.

- A Programming Logic Controller is an industrial computer adopted for industrial automation to control various manufacturing processes like assembly lines, machines, robotic devices, or some kind of activity with high dependability, no difficulty in programming, & identification of process faults.

- But knowing the history of PLC this was invented by Dick Morley, and developed by Modicon technologies.

How PLC Programming languages can be classified?

According to Section 61131-III Std of the International Electro-technical Commission (IEC). PLC Programming Languages can be classified into

- Ladder Logic /Diagram.

- Function Block Diagram.

- Sequential Function Charts.

- Structured Text.

- Instruction List.

- As seen above there are five different PLC programming languages that a personal computer with Windows operating system supports to develop the logic or a program based on process requirements to monitor and control the existing process.

- There are various PLC controllers with their unique programming software that are readily available in the market through this software a programmer can easily design the Logic to control the process.

- Basically, as we all know Ladder Logic/Diagram is the most familiar and well-known Programming Language.

- But some controllers support both Function Block Diagram and Ladder Logic Diagram for PLC programming.

Can we use a PC as a PLC?

-

Yes, we can use a PC as a PLC.

-

The PC that we are using as a PLC must be loaded or installed with the respective Programming software.

-

For example, If we are using Allen Bradley Micrologix PLC then we must have RSLinx Classic, RSLogix Emulate 500 software installed,

-

If we are using a PLC of ABB make then we must have Automation Builder software installed.

-

Likewise, there is various programming software available, but the programmer must select the right software and its version for which PLC model he is using.

-

During the designing of particular logic, the programmer must be familiar with both Analog & Digital Input/Output because Input & Output Address & Memory address varies for various PLC Brands.

-

For example, if we are using Allen Bradley Micrologix 1400 PLC of Bulletin Number 1766, the I/O & Memory Address is as follows.

- Input Address: I1:0/0 to I1:0/15 16 Bit, and I1:1/0 to I1:1/3 4 Bit.

- Output Address: O0:0/0 to O0:1/11 12 Bit.

- Memory Address: B3:0/0 to B3: 0/15 16 Bit.

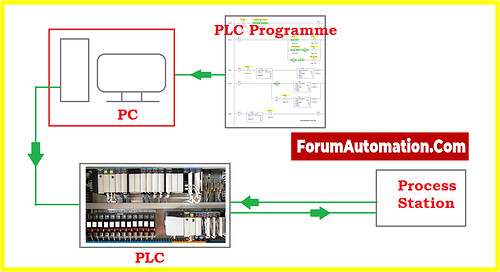

- After designing Logic or a program in the PC, the same can be used as a PLC to monitor and control the process station through simulator mode. For this, there is no need to download the program to the respective PLC but can be easily achieved through simulator mode just by following the execution steps provided.

- We don’t need PLC controller to assemble, compile or modify a Program to run a process. This can only be done on the PC itself. Just by uploading the logic from PLC to PC.

- But if there is any malfunction in the program, it is compiled and checked for error, after ensuring the program is error free the same program can be downloaded from the PC to the respective PLC controller.

- Downloading a Program from PC to PLC or Uploading a program from PLC to PC is achieved through the communication port provided.

- Usually, Ethernet is a commonly used communication protocol for various PLC controllers.

Is it possible to use a PC instead of a PLC?

- Compared to PCs these PLCs are cheaper without any external peripherals that need to be added.

- Since Industrial PLCs have the ability to support standard industrial equipment.

- A PC-based solution is considered a better one compared to a PLC-based solution. When there is a need for too many external controls.

How PLC controller can be linked to a PC?

- PLC controller can be linked to a PC through an RS-232 cable.

- Here, One end of the RS-232 cable is connected to a (9-pin or 25-pin connector) serial port of the PC, while the other end of the RS-232 cable is linked to an RS-232-C connector on the RS-232 module of a CPM-1-A controller.

Are PLC programs designed on a PC?

- Yes, through the use of standard computers, most PLCs can be programmed by using their unique programming software.

- PLC programming is done in five different languages defined by International Electrical Code (IEC) 61131-III standard.

- Among five programming languages

- Three languages use graphical interfaces for programming.

- Two languages use text interfaces for programming.

How is a PC used with a PLC?

In some PLC Controllers, the logic is conveyed from PC to PLC via a programming board that loads the logic into a removable chip like EPROM.

Why PLC is better than PC?

A PLC is designed for reliable operation in very harsh industrial environments. PLC has the ability to resist heat, cold, dust, and other nasty environmental conditions.

Why use PLC instead of PC?

- Since PLCs are

- Rugged,

- Cost-effective, and

- Highly secure for industrial positioning.

But industrial PCs are best for solutions with high demand in computing and storage.