How to check instrument earthing?

How to check instrument earthing?

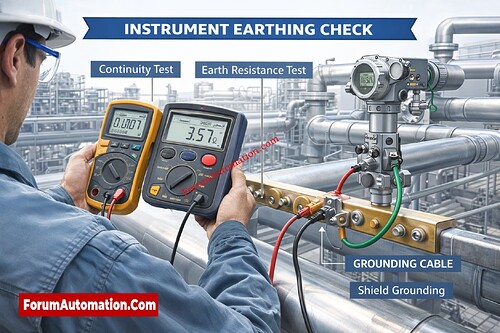

To keep people safe, make sure the instruments are properly grounded. This will also protect them from electrical noise and lightning. It is standard to check instrument earthing during commissioning, maintenance, and safety audits.

Step-by-Step Method to Check Instrument Earthing:

-

Visual Inspection Make sure that the earthing conductor is properly attached to the instrument body and the right earth bar before anything else. Look for loose terminals, corrosion, paint on contact surfaces, or damaged earth wires. Make that the size of the earth cable matches site standards.

-

Continuity Test Put your digital multimeter in continuity mode. Put one probe on the body of the instrument and the other on the main earth bar. A path with low resistance shows that the bonding is correct.

-

Earth Resistance Measurement Use an earth resistance tester (megger or earth tester) to find out how much resistance there is between the earth electrode and genuine ground. Usually, the resistance of an instrument’s earth should be less than 1 ohm, but this may not always be the case.

-

Separation Check Make sure that the instrument earth and power earth are not connected to each other to avoid noise coupling, especially for analog signals like 4–20 mA.

-

Noise and Shield Verification To avoid ground loops, make sure that the cable shields are only grounded at one end, which is usually the control room.

Correct earthing is an important but often neglected chore that makes measurements more stable, reduces signal drift, and preserves expensive instruments.