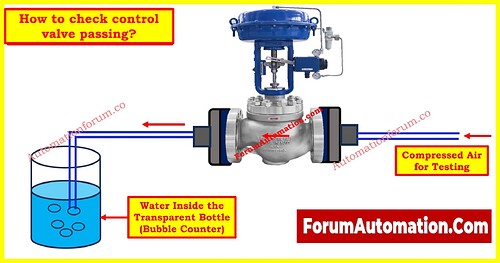

How to check control valve passing?

How to Check Control Valve Passing

A passing control valve is a valve that lets flow through even when it is completely closed. For process safety, energy efficiency, and precise control, it is very important to be able to find this situation. Industries employ a number of practical ways to check if a control valve is passing:

1. Visual Inspection (Leak Test)

- Close the valve all the way.

- Bring in test fluid from the outlet side.

- The valve passes the test if there is no visible leakage from the packing, gasket, or sealing surface.

- Any visible leak means that the valve has passed.

2. Instrument Indication

- For gas service, a downstream pressure gauge or transmitter that shows a pressure rise (higher than zero) even when the command is closed means there is a leak.

- For liquid service, a flow transmitter or flow indicator that detects continuous flow downstream also certifies that the valve is passing.

3. Open Drain Verification

- Close the control valve all the way.

- Check for leaks by opening the drain valve downstream.

- The valve is passing if liquid or gas keeps leaking.

Note: For gases, take strict safety precautions because venting might be dangerous.

4. Control Signal Test

- To close the control valve, either cut off the air supply or set the controller output to 0% (fail-close type).

- Watch the flow transmitter (FT) or pressure transmitter (PT) in that loop. Any reading that stays the same for a long time shows a leak.

If a control valve doesn’t shut off completely, it needs to be fixed or replaced. Regular passing inspections are necessary to keep the process running smoothly and make sure safety rules are followed.