How does a Gas Generator generate Electricity?

Gas generators are commonly utilized as backup power sources in enterprises, households and companies.

But how do they make power from gas fuel?

Let’s take the full process by step-by-step procedure

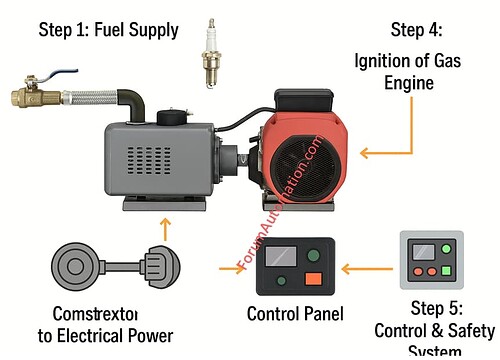

Step 1: Fuel Supply

A gas generator’s operation starts with the fuel supply.

The generator can be powered by

- Hydrogen,

- Liquefied Petroleum Gas (LPG),

- Biogas or Natural Gas

depending on its design.

A specifically built fuel line or controlled piping system delivers this gasoline to the generator’s engine.

Once the engine is operating, the supply system makes sure the gas is provided at the proper pressure and volume allowing for steady and even combustion.

Step 2: Ignition of Gas Engine

The ignition process starts as soon as the fuel enters the combustion chamber.

This is accomplished in the majority of gas generators by either an auto-ignition system or spark plugs.

Combustion results from the spark lighting the air-fuel mixture inside the cylinder.

High pressure is created inside the cylinder as a result of the explosion caused by the fuel burning so quickly.

By forcing the piston downward, the pressure transforms the fuel’s chemical energy into the initial phase of mechanical energy.

Step 3: Mechanical Power Generation

The crankshaft receives the downward force generated by combustion in the piston.

The crankshaft revolves constantly while the piston repeatedly rises and falls.

The engine’s primary source of mechanical energy is this rotation.

No additional conversion into electricity could be feasible without this mechanical power.

The generator performs better when the piston-crankshaft action is smoother and more effective.

Step 4: Conversion to Electrical Power

The alternator (generator unit) is directly connected to the rotating crankshaft.

The stator stays motionless inside the alternator, whereas the rotor rotates.

The stationary stator windings are cut through by the rotating magnetic field produced by the rotor.

According to Faraday’s law of electromagnetic induction, this interaction causes an electrical current to flow through the stator coils.

At this precise moment, mechanical energy is converted into electrical energy.

Step 5: Power Output

Alternating current (AC) is the usual form of electricity produced inside the alternator.

Before being transferred to the linked loads, this output is first subjected to voltage and frequency regulation.

The output of the generator can then be used directly to power fans, lighting, appliances, machinery and industrial equipment.

For stability and safety, the electricity may also be dispersed via circuit breakers or transfer switches, depending on the generator’s size and construction.

Step 6: Control & Safety System

In order to operate safely, a gas generator needs to be watched over and managed in addition to producing electricity.

In this case, the control panel is essential. It monitors critical factors like load demand, voltage, frequency, and gas flow.

To avoid damage, the control system immediately modifies operations or turns off the generator in the event of anomalies such

- Overloads,

- Overheating (or) Pressure changes.

This guarantees the generator’s safe, effective and dependable operation while producing electricity.

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.