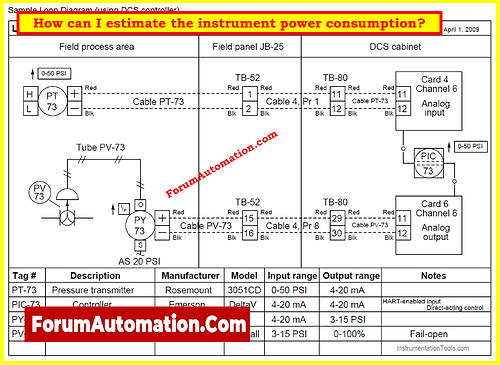

How can I estimate the instrument power consumption?

First, look at the datasheet. Find the rated supply voltage (V), operational current (I), or power (W), as well as any inrush or current spikes. You’re done if the datasheet gives watts.

Simple formulas

DC or single-phase (resistive): P = V × I (watts).

P = V × I × cosφ for AC with a power factor.

Three-phase: P = √3 × V_line × I_line × cosφ. 4–20 mA loops P = V_supply × I_loop or if you know device burden voltage VbV_bVb: P_device = V_b × I_loop

Battery runtime: Energy (Wh) = Ah × V; runtime (hours) = **Energy (Wh) / P (W)

Example:** A 4–20 mA transmitter with max loop current 20 mA on 24 V: P = 24 V × 0.02 A = **0.48 W

When in doubt, measure. For current, use a clamp meter; for voltage, use a multimeter; and for mains instruments, use a plug-in power meter. Log over time to see the peaks of idle and active times.

Add peripherals and derating. Add power for screens, heaters, valves, communications modules, and take into account starting and inrush. Add a safety margin of 20 to 30 percent to make sure the PSU is the right size and works.

Write down and size the PSUs. Add up the powers of all the instruments, add a margin, and pick a PSU that has the right voltage, current rating, and protections.

Following these procedures will help you make accurate estimations for battery size, energy budgeting, and supply choices.