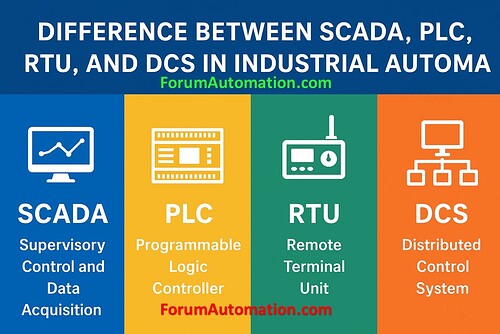

SCADA (Supervisory Control and Data Acquisition)

SCADA is a centralized software-based system that monitors & controls geographically distributed operations by collecting real-time data from the field devices showing it on HMI panels, and allowing remote control actions.

PLC (Programmable Logic Controller)

A PLC is a rugged industrial controller that performs user-programmed logic in real time to operate the machinery, equipment & processes, and is frequently used as the primary control device in automation.

RTU (Remote Terminal Unit)

An RTU is a field-deployed device that collects data from sensors, sends it to a control center & executes control commands, usually from remote places via wired or wireless communication.

DCS (Distributed Control System)

A distributed control system (DCS) is a plant-wide control architecture that combines many dispersed controllers, coordinated by a central supervisory system to automate & optimize complex industrial processes continuously.

| SCADA | PLC | RTU | DCS |

|---|---|---|---|

| SCADA is a supervisory control and data acquisition system that monitors and controls large-scale, geographically distributed industrial activities. | A programmable logic controller (PLC) is a device that uses programmed logic to manage machines and equipment directly and in real time. | RTU is a remote terminal unit that collects data from sensors at remote areas and sends it to the central control system while carrying out specific commands. | DCS is a distributed control system that manages & optimizes continuous industrial operations using many controllers located across the plant. |

| SCADA systems are often housed in a central control room & communicate with several remote sites via PLCs, RTUs, and sensors. | PLCs are situated close to machinery within control panels to directly control actuators, motors & process devices. | RTU is used in outdoor or remote field settings such as power substations (or) pumping operations. | DCS is used in multiple process areas within the same facility, with local controllers connected to the central monitoring system. |

| SCADA operates at supervisory level, with emphasis on data visualization, alerts, and high-level control. | PLCs function at the field level, carrying out control actions in ms (milliseconds). | RTU primarily acts on the data acquisition level, sending field data & performing basic logic. | DCS functions at the process level, providing the consistency, efficiency & automation of the continuous production. |

| SCADA interacts with PLCs and RTUs through industrial communication protocols such as Modbus, DNP3, and OPC. | PLCs communicate with SCADA or DCS systems via Ethernet, Modbus (or) fieldbus protocols. | The RTU communicates with SCADA via serial, fiber optic (or) wireless communications. | DCS enables distributed controllers to communicate in real time via high-speed plant networks. |

You can also follow us on AutomationForum.co, Facebook and Linkedin to receive daily Instrumentation updates.

You can also follow us on ForumElectrical.com , Facebook and Linkedin to receive daily Electrical updates.